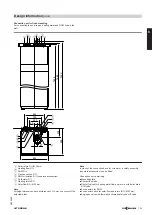

Neutralising system

C

B

A

A

Condensate drain

B

Neutralising system

C

Ventilation via the roof

The Vitodens can (if required) be supplied with a separate neutralis-

ing system (accessories, see page 69). Any condensate is piped to

and processed in the neutralising system.

The condensate drain pipe to the sewer connection must be accessi-

ble for inspection. Install it with a fall and a stench trap on the sewer

side, and provide a suitable facility for extracting samples.

Install a condensate lifting pump if the Vitodens has been installed

below the waste water anti-flooding level.

Condensate lifting pumps are available as accessories.

Since the consumption of neutralising granulate depends on the

operating mode of the system, carry out regular checks during the

first year of operation to determine the required top-up volume. One

fill can last longer than one year.

Condensate removal pump (accessories)

C

A

B

A

Condensate inlet

B

Condensate removal pump

C

Condensate drain

8.5 Hydraulic connection

General

System design

Viessmann condensing boilers can generally be installed in any fully

pumped hot water heating system (sealed unvented system).

The circulation pump is an integral part of the appliance.

Minimum system pressure 1.0 bar (0.1 MPa).

The boiler water temperature is limited to 82 °C.

To minimise distribution losses, we recommend sizing the heat distri-

bution system to a max. flow temperature of 70 °C.

Due to the immediate capture of the room influence factors, we rec-

ommend using the Vitodens in conjunction with the Vitotrol 200-E for

apartments with less than 80 m

2

living space or for low energy

houses with a low heat demand.

The heat generator must be correctly sized and selected.

Chemical anti-corrosion agents

According to VDI guideline 2035, the design of heating systems

must ensure they are sealed against corrosion. Additives in the heat-

ing water (additives, chemicals) as corrosion protection measures

are normally not necessary.

Exception: In systems without system separation, for example, addi-

tives can be considered.

Heating circuits

For heating systems with plastic pipes, we recommend the use of

impermeable pipes to prevent the diffusion of oxygen through the

pipe walls.

Provide system separation in heating systems with plastic pipes that

are permeable to oxygen (DIN 4726). A separate heat exchanger for

this purpose is available.

Install a dirt separator in underfloor heating systems. See

Viessmann Vitoset pricelist.

Underfloor heating systems and heating circuits with very large

water content (>15 l/kW) should be connected to the condensing

boiler via a 3-way mixer. See technical guide "Control of underfloor

heating systems" or the relevant sample applications.

Install a temperature limiter in the flow of the underfloor heating cir-

cuit to restrict the maximum temperature. Observe the requirements

of DIN 18560-2 [or local regulations].

Plastic pipework for radiators

We also recommend the use of a temperature limiter to restrict the

maximum temperature for plastic pipework in heating circuits with

radiators.

Attic heating centre

The installation of a low water indicator, compulsory according to the

DVGW [Germany], is not required when installing boilers in an attic

heating centre.

The boilers are protected against water shortage in accordance with

EN 12828.

Safety valve

A safety valve in accordance with TRD 721 is integrated in the

Vitodens (opening pressure 3 bar (0.3 MPa)).

Design information

(cont.)

134

VIESMANN

VITODENS

8

5853906

Summary of Contents for Vitodens 200-W B2HE

Page 154: ...154 VIESMANN VITODENS...

Page 155: ...VITODENS VIESMANN 155 5853906...