12

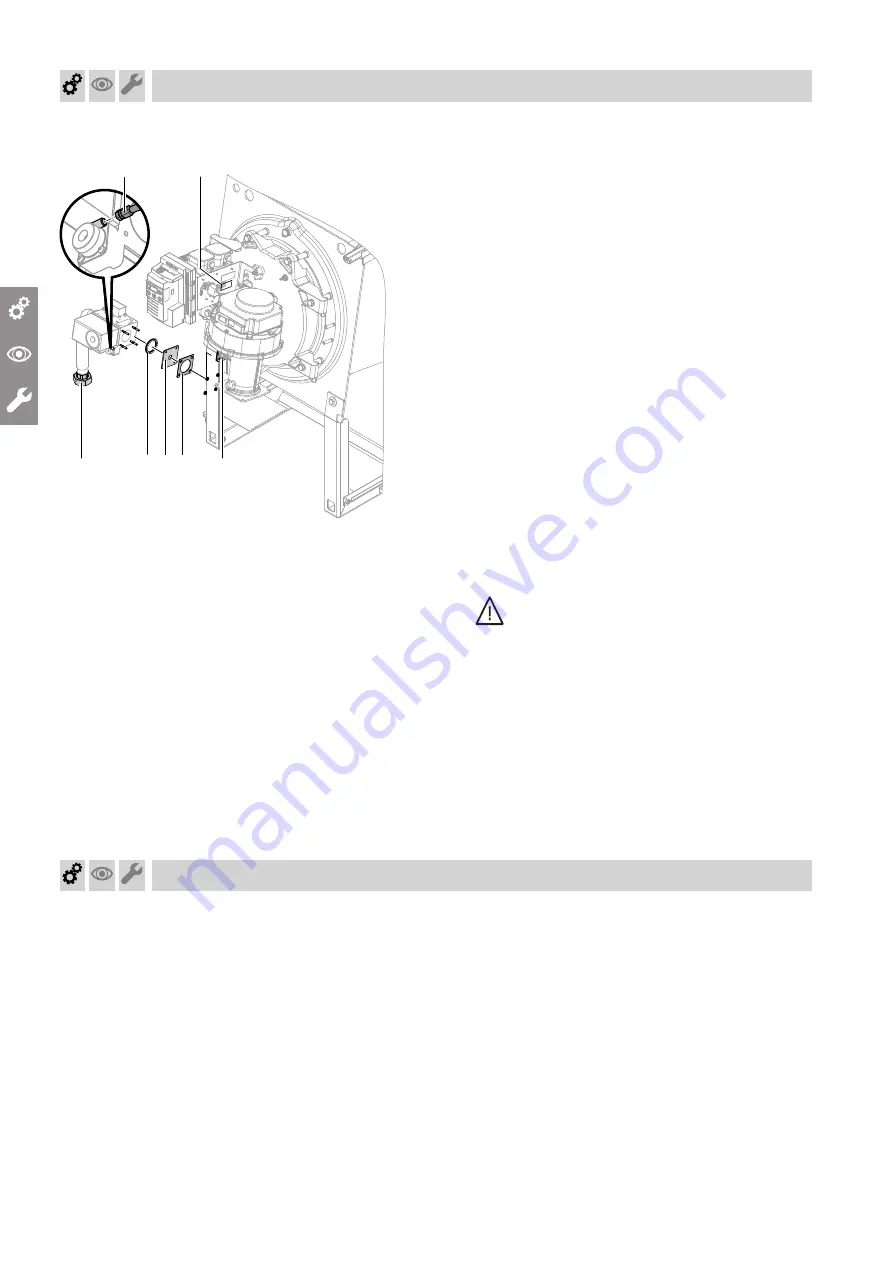

Conversion with 115 to 311 kW rated heating output

F

A

BCD

E

G

Fig. 3

0

1.

Close the gas shut-off valve.

0

2.

Switch off the system ON/OFF switch at the user

interface of the control unit.

0

3.

Switch OFF the mains isolator (outside the instal-

lation room) or isolate the mains power and

secure against unintentional reconnection.

0

4.

Undo fitting

A

.

0

5.

Disconnect control cable

G

from the gas train.

0

6.

Release the gas train from flange

E

.

0

7.

Remove restrictor

C

with rubber cork gasket

D

.

0

8.

Secure the gas train to flange

E

:

■

with O-ring

B

■

without restrictor

C

■

without rubber cork gasket

D

Torque for M 5 nuts: 1.5 Nm

0

9.

Secure fitting

A

with a new gasket.

10.

Plug control cable

G

into the gas train.

11.

Check control cables:

■

Connection and kink-free routing

■

Application and seating of retaining clips

12.

Where present for set gas type: Affix label "Set

to ..."

F

supplied over the existing label.

13.

Start the burner.

14.

Check for gas tightness.

Danger

Escaping gas leads to a risk of explosion.

Check gas routing components for leaks.

!

Please note

The use of leak detection spray can result in

faulty operation.

Leak detection spray must not come into

contact with electrical contacts.

Note

For control cable locations, see page 27.

Conversion to LPG P

Conversion to LPG P only with 186 to 311 kW rated

heating output

Commissioning, inspection, maintenance

Conversion to natural gas L

(cont.)

5831036