33

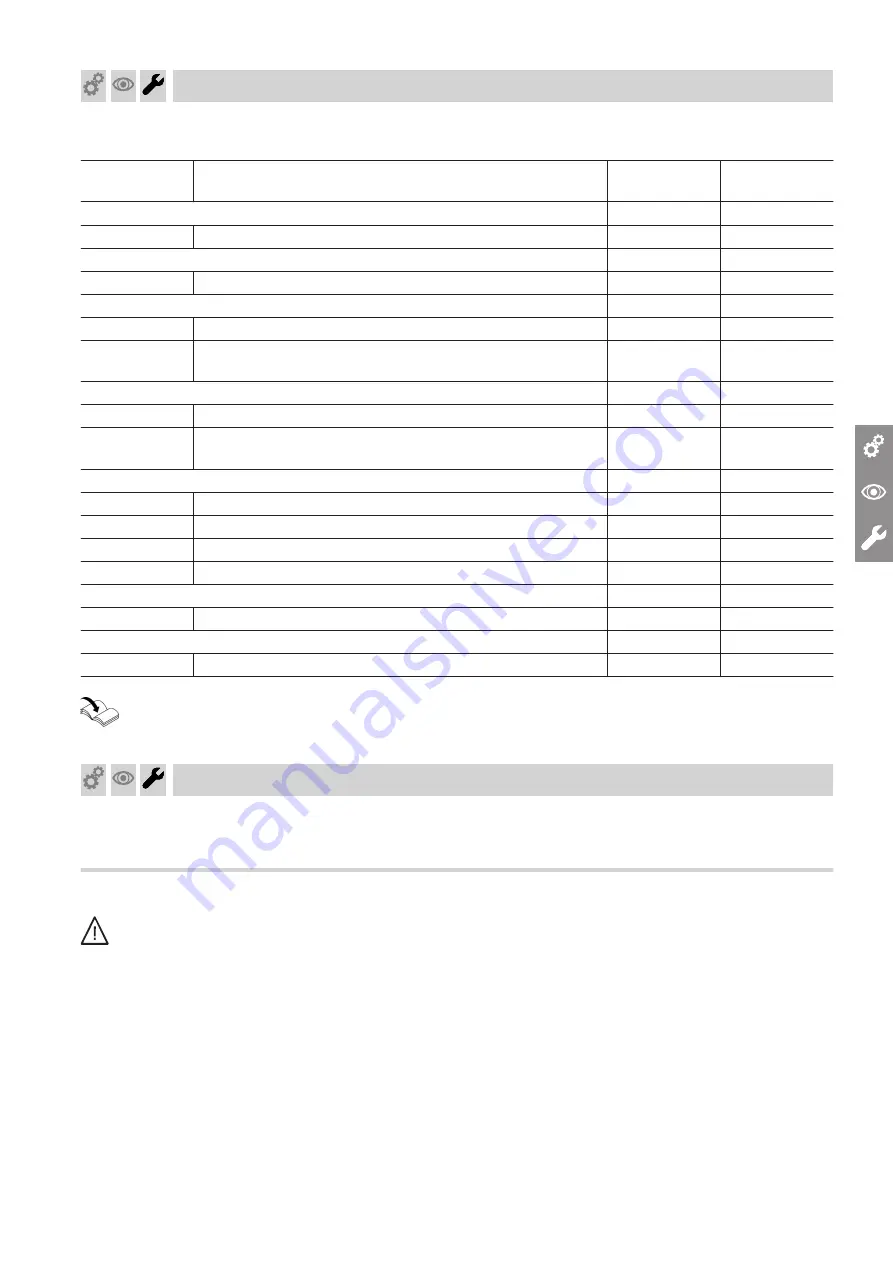

Overview of maintenance and cleaning work

Interval

Activity

System user

Heating con-

tractor

Before every heat-up

Check the ash chamber, clean if necessary.

X

Weekly

Clean the ash chamber.

X

After 100 hours run

Clean the tubular heat exchanger.

X

Check the fill level of the tubular heat exchanger ash pan,

empty the container if required.

X

After 300 hours run

Clean the sight glass.

X

Check the combustion chamber for deposits, clean if neces-

sary.

X

After 900 hours run, and at least once a year

Clean and calibrate the Lambda probe.

X

Clean the flue gas fan.

X

Check all gaskets for damage; replace if required.

X

Check the thermally activated safety valve for tightness.

X

Twice yearly

Thoroughly clean the boiler.

X

Every 5 years

Replace the battery inside the control unit.

X

Tasks for the system user

See operating instructions

Cleaning and calibrating the Lambda probe

Note

The Lambda probe can only be calibrated manually.

Cleaning the Lambda probe

Danger

A hot Lambda probe may cause burns.

■

Allow the Lambda probe to cool down before

removing.

■

Wear safety gloves.

1.

Remove the Lambda probe from the flue outlet.

2.

Clean the Lambda probe with a soft brush and vac-

uum cleaner.

3.

Check the Lambda probe for damage and replace

if required.

4.

Check the connecting cable for possible damage.

Notes

■

Do not paint, wax or treat the probe with any other

such substance. Only use special grease suitable for

Lambda probes to grease the threads.

■

The Lambda probe receives its reference air via the

connecting cable. For this reason, ensure that the

connection plugs are kept clean and dry and do not

treat them with contact spray, anti-corrosion agents

etc.

■

Do not solder the connecting cable; it must be crim-

ped, clamped or secured with screws.

Commissioning, inspection, maintenance

Maintenance and cleaning intervals

(cont.)

5684984