UG:309

Page 4

Software Installation and Operation

Users downloading the

should save the compressed file in a desired directory. The user should

unzip the compressed file and run the executable installation file “PicorBuckGuiFull_setup.exe”. The

installer will then install the Buck GUI in either the default Programs directory or to a directory specified

by the user. Once the software is installed, the user should next plug in the LinkM™ into a dedicated

USB port. The LinkM will detect and use a valid driver without the need of installing one. If the LinkM

device is not detected, the user should consult the LinkM

. If the LinkM is not installed, the

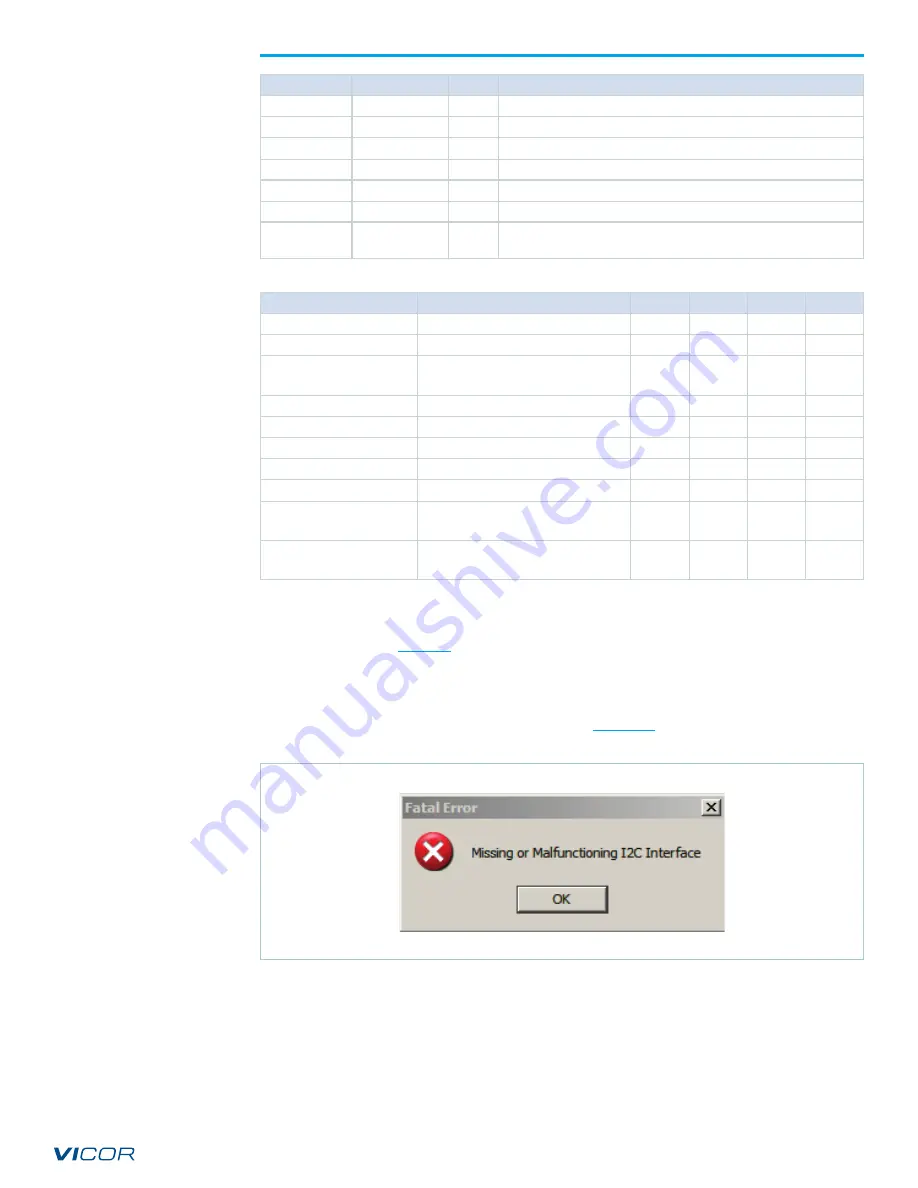

Buck GUI will not start and an error message will be generated like the one shown in Figure 3.

Successful installation of the LinkM Interface should result in a successful start up screen of the Buck

GUI as shown in Figure 4. First a dialog box will pop up indicating proper detection of the LinkM. When

the user clicks the “OK” button, that box will disappear. The Buck GUI program screen will appear as

shown in the bottom half of Figure 4.

Table 2

User‑accessible registers

Table 3

I

2

C™ port specifications

Figure 3

Error message due to missing

LinkM upon software start

Name

Address HEX

# Bits

Description

TSTMDE[2:0]

18

3

Test mode register used for burning bits into non‑volatile memory

MRGN[3:0]

19

4

Volatile register for output voltage margining

FLT[7:0]

1A

8

Fault Register read only

FREG_CLR

1B

0

Register for clearing the Fault Register‑writing address clears register

ENA_POL

20

1

EN pin polarity programming bit

SYN[3:0]

21

4

SYNC programming. SYN[3] = SYNC polarity

KBIT2

22

1

User kill bit for SYN[3:0] and ENA_POL –

can not be reversed;

register is write only, can not be read

Parameter

Conditions

Min

Typ

Max

Units

SCL, SDA V

IH

Rising, 3.3V & 5V bus compatible

2.1

V

SCL, SDA V

IL

Falling 3.3V & 5V bus compatible

1.5

V

SCL, SDA input current

(sink to hold open pins low)

At 5V

1.8

5

10

µA

SDA V

OL

3mA

0.4

V

ADDR0,1V

MID

V

CC

= PI33xx‑xx fixed, internal 5.1V

0.4V

CC

0.6V

CC

V

ADDR0,1V

IH

V

CC

= PI33xx‑xx fixed, internal 5.1V

0.8V

CC

V

ADDR0,1V

IL

V

CC

= PI33xx‑xx fixed, internal 5.1V

0.1V

CC

0.2V

CC

V

ADDR0,1 hysteresis

0

mV

ADDR0,1 Output resistance

from ½ V

CC

0.3V

CC

< ADDRx < 0.7V

CC

V

CC

= PI33xx‑xx fixed, internal 5.1V

6k

kΩ

ADDR0,1 Output resistance

from ½ V

CC

ADDRx < 0.2V

CC

, ADDRx > 0.8V

CC

V

CC

= PI33xx‑xx fixed, internal 5.1V

70k

kΩ

Summary of Contents for PI33 EVAL1 Series

Page 13: ...UG 309 Page 13 Figure 14 PI33xx xx SYNC 1000 timing Figure 15 PI33xx xx SYNC 1111 1 4MP ...

Page 14: ...UG 309 Page 14 Figure 16 PI33xx xx SYNC 1110 1 3MP Figure 17 PI33xx xx SYNC 1101 1 2MP ...

Page 15: ...UG 309 Page 15 Figure 18 PI33xx xx SYNC 1100 2 3MP Figure 19 PI33xx xx SYNC 1001 3 4MP ...