Rev. 5/8/2019

ZLTT MANUAL

Copyright 2019 Vestil Manufacturing Co.

Page 10 of 15

Loading the Table

ZLTT-series tables include a backstop feature to retain loads

while the tabletop is tilted. The open side of the table provides a

tapered edge for pallet trucks to access the table interior. The

backstop will be lower than the open side of the table when it is

tilted so the load must rest against the backstop when it is applied

to the table. Otherwise, as the table tilts the load will slide. The

load should also be centered against the backstop. The load

center should be no more than 36 inches above the tabletop.

Sequence of Operation

Powered lift and tilt functions are provided by an electric-hydraulic power unit (EHPU). The EHPU uses an

electric motor coupled to a gear-type hydraulic pump to pressurize the hydraulic system. Hydraulic pressure

allows the cylinders to extend. Cylinder extension lifts and tilts the tabletop. Control components are housed

inside a manifold bolted onto the gear pump. All hydraulic components are rated for 3,000 psi working pressure.

Standard units utilize a 4-button, constant pressure (dead man), push-button controller. Pressing the LIFT

button extends the lift cylinder and raises the tabletop. The tabletop remains horizontal. Press the TILT UP button

to tilt the tabletop up to a maximum angle of 45°. The table moves only as long as a button is pressed. The

tabletop stops as soon as the button is released and maintains position until a button is pressed.

Notable parts of the power unit include:

•

Electric motor: Used to power the hydraulic system. The motor is either single-phase AC or three-phase AC

as selected by the customer. Regardless of phase, every motor is dual-voltage capable.

•

Gear pump: The pump shaft is coupled directly to the shaft of the electric motor. Several displacements are

available to match the horsepower of the motor selected.

•

Check valve: Prevents backflow of fluid through the pump. This allows the tabletop to maintain

position/configuration when the handheld controller is not in use.

•

Pressure relief valve: This valve opens a path for fluid to flow back to the reservoir if fluid pressure exceeds

3,000psi. The relief valve is a safety feature designed to prevent damage to the hydraulic system that would

otherwise be caused by excessive pressure.

•

Lowering solenoid valve: An electrically-operated cartridge valve with an integral screen. The screen prevents

contaminants from entering the valve.

•

Pressure compensated flow control spool: The spool determines the cylinder retraction speed and thereby

fixes the lowering speed of the tabletop. The spool is located beneath the lowering valve. This component

allows the tabletop to descend at a constant rate regardless of the weight applied to it.

•

Hydraulic cylinders: Extend and retract to change the configuration of the tabletop. Each cylinder includes a

bleeder valve located at the top end. The bleeder allows air to be removed from the hydraulic system.

•

Velocity fuse: A safety device installed in the hose port of each cylinder. The fuse closes automatically if a

sudden, significant drop in hydraulic pressure occurs. A closed fuse traps oil inside the cylinder which

prevents the cylinder from retracting further. Consequently, the tabletop remains stationary until system

pressure is reestablished.

•

Hydraulic fluid: HO150 hydraulic fluid. Only use anti-wear hydraulic fluid with a viscosity grade of 150 SUS at

100°F (ISO 32 @ 40°C) like AW-32 or Dexron transmission fluid.

Operating the Table

A. LIFT and LOWER functions

1. Raise the tabletop by pressing the LIFT button.

•

The motor turns and rotates the gear pump. While the pump rotates, oil

is drawn out of the reservoir.

•

Oil passes through the suction filter and enters the pump.

•

The pump propels oil through the check valve and towards the lift

cylinders.

•

Releasing the button immediately halts the tabletop.

•

A limit switch automatically turns off the motor when the tabletop

reaches its maximum height.

2. Lower the tabletop by pressing the LOWER button.

•

The lowering valve opens and bypasses the check valve. Oil in the

cylinder flows to the reservoir. Oil flow is regulated by the pressure

compensated flow control valve. By regulating the volume of oil that

can flow through the spool, the speed at which the tabletop lowers is

constant.

Load firmly

contacts

backstop

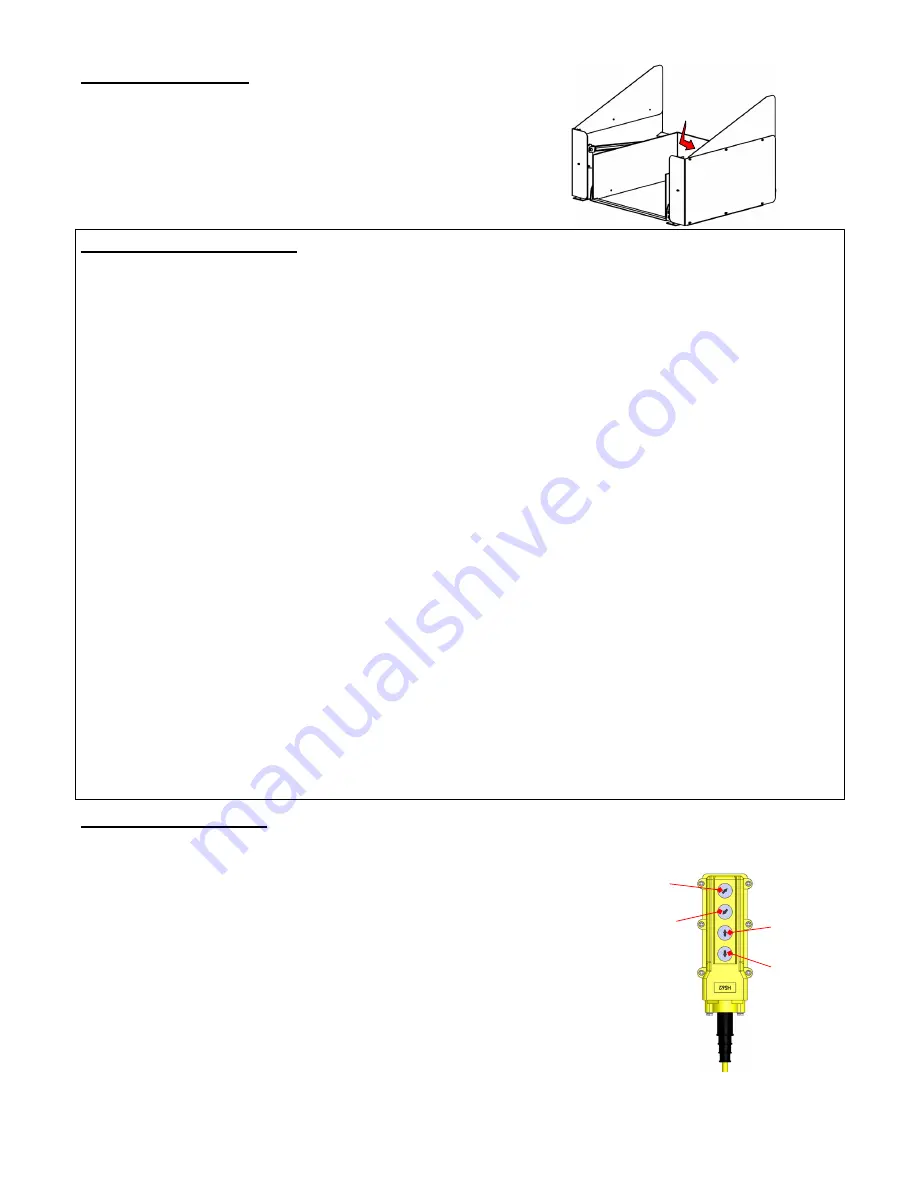

Handheld Controller and

Control Buttons

TILT

UP

TILT

DOWN

LIFT

LOWER