Operator’s Manual

2/2/21

EHLT, MANUAL.DOCX

Copyright 2020, Vestil Manufacturing Corp.

Page

22

of

24

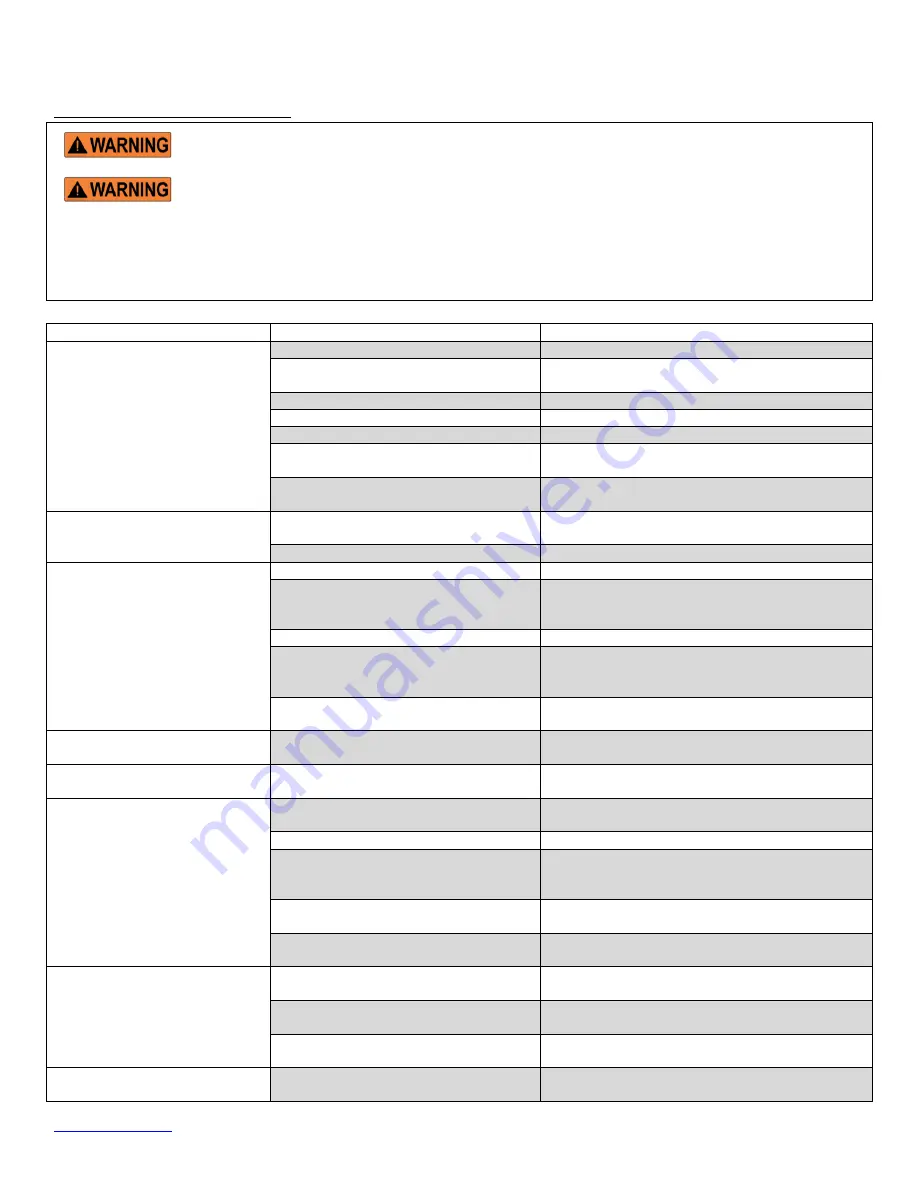

TROUBLESHOOTING GUIDE

Care should be taken to identify all potential hazards and comply with applicable safety procedures

before beginning work.

Remove any load and install the maintenance props before beginning any inspection or service on

the lift table. See below.

Only qualified individuals trained to understand mechanical devices, electrical and hydraulic circuits, and the hazards

associated with them, should attempt troubleshooting and repair of this equipment.

Consult the factory for any problems not addressed in this manual. ALWAYS have the product serial number or model

number on hand when calling the factory.

PROBLEM

POSSIBLE CAUSES

ACTION

Power unit doesn’t run when “UP”

button is pressed.

Transformer fuse is blown.

Test with meter. Replace if bad.

No supply voltage.

Test with meter. Check fuses, breakers, and overloads to

determine the cause

Upper-travel limit switch is engaged or bad.

Inspect and test switch. Replace if bad.

Bad control transformer.

Check for 24 VAC at secondary. Replace if bad.

Bad motor relay coil.

Test with meter. Replace if bad.

Bad solenoid start switch (DC units).

The green LED on motor relay will be off, or will turn off

when the UP pushbutton is pressed.

Battery voltage low (DC units).

Test with meter. Charge battery if low (is the motor relay

LED on?)

Motor runs but platform doesn’t

move. Power unit not noisy.

Motor rotation is wrong (AC-powered units

only).

Verify the motor runs CW, opposite the shaft end.

Pump is failing to produce pressure.

Consult factory.

Motor hums or pump squeals, but

the platform does not move, or the

platform moves only slowly.

Pump is failing to produce pressure.

Consult factory.

Excess voltage drop to motor, due to power

wire size too small, wire run to long, or

incoming voltage too low.

Check the power installation for adequacy. Check the

incoming voltage

while the motor is running

. Correct

any problems found.

Motor is “single-phasing”.

Determine and correct cause of voltage loss on phase.

Pressure relief opening at full pressure.

Check for structural damage or binding of the scissor

legs, etc.

Check for platform overload condition.

Contamination holding open the lowering

valve or the check valve.

Remove and inspect valves. Clean per instructions in the

“Inspection and Maintenance” section.

Platform raises, then drifts down.

Contamination holding open the lowering

valve or the check valve.

Remove and inspect valves. Clean per instructions in

“Inspection and Maintenance” section.

Spongy or jerky platform movement.

Excessive air in the hydraulic cylinders.

Bleed air per procedure described in the “Inspection and

Maintenance” section.

Platform won’t lower.

Perimeter toe guard actuated.

Check for a toe guard extrusion or rubber corner that is

stuck. Adjust if necessary.

Perimeter toe guard switch or wire broken.

Inspect visually; check with mutimeter. Repair as needed.

Solenoid coil is bad.

Check with multimeter using the diode-check function.

(Reading for ohms will not provide an accurate test of

the coil). Replace if bad.

Physical blockage of the mechanism.

Inspect for foreign material or objects blocking the

scissors or the rollers.

Solenoid valve, flow control, or suction hose

screen plugged.

Remove and inspect valves. Clean per instructions in

“Inspection and Maintenance” section.

Platform lowers too slowly.

Solenoid valve, flow control, or suction hose

screen plugged.

Remove and inspect valves. Clean per instructions in

“Inspection and Maintenance” section.

Velocity fuse locking (indicated by platform

only slowly creeping down).

Check for air in hydraulic system. Bleed air as needed.

Flow control valve spool sticking.

Remove and inspect valves. Clean per instructions in

“Inspection and Maintenance” section.

Platform lowers too quickly.

Flow control valve spool sticking.

Remove and inspect valves. Clean per instructions in

“Inspection and Maintenance” section.