24

VEGASON 51K … 53K

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;

;;

;;

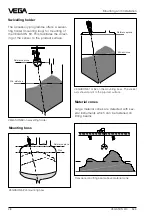

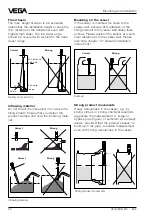

If possible, provide a vertical directing of the

sensor axis to the product surface and

avoid, if possible, struts within the 100 %-

beam, e.g. by tubes and struts.

Min. distance, max. measuring range and span (example VEGASON 51, 52 and 53)

4 m (type 51), 7 m (type 52), 15 m (type 53)

4 Mounting and installation

4.1 General installation instructions

Measuring range

You select your instrument according to the

required measuring range, as well as other

criteria. The reference planes for the min. and

max. distance to the product or the solid is

either the transducer surface (diaphragm) or,

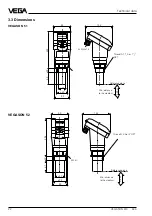

Mounting and installation

on instruments with flange version, the instru-

ment flange. (Note the information for the

reference planes in chapter "Dimensions“).

The max. filling is dependent on the required

min. distance of the instrument used (0,25 m

to 1,4 m) and the installation place of the

instrument or the transducer.

Full

Span

Min.

distance

1m

Empty

Min.

distance

Min.

distance

0,25 m

0,4 m

0,75 m

Reference plane

Type 51

Type 53

Type 52

Beam angle and false echoes

The ultrasonic impulses are focussed by the

transducer. The impulses leave the trans-

ducer in conical form similar to the beam

pattern of a spotlight. The beam angle is 5,5°

(VEGASON 51/52) or 3° (VEGASON 53) at

-3 dB emitted power.

Any object in this beam angle causes a false

echo. Within the first few metres of the beam

angle, tubes, struts or other installations

cause strong false echoes. At a distance of 6

m the false echo of a strut has 9-times more

amplitude than at a distance of 18 m.

max. meas. range