Appendix A: EMR4 Safety Instructions & System Specifications

EMR4

S

ystem

S

pecifications

A-2

All ATEX models of the

EMR4

DH

are in compliance with Directive

2014/34/EU (ATEX)

.

A sample EMR4 DH has been evaluated and tested by

UL International Demko A/S

, Borupvang 5A, 2750

Ballerup, Denmark Tel.+45 44 85 65 65,

,

and approved by the issue of the EC type

certificates:

DEMKO 17 ATEX 1889X

o

r

IECEx UL 17.0054X

EMR4 Display Head

EMR4 Remote Encoder

Symbol

X

used as suffix in all of the EC type test certificates listed above indicates the need for observing

special conditions for safe use.

Further information is provided in each respective EC type certificate under the

paragraph,

SPECIAL CONDITIONS FOR SAFE USE

.

The manufacturers Quality System has been reviewed and is notified by

SGS Baseefa, Staden Lane, Buxton,

Derbyshire SK17 9RZ, United Kingdom

authorizing the use of its ID

1180

in conjunction with the CE mark. The

manufacturer is notified via SGS Baseefa QAN No. BASEEFA ATEX 1968. The CE mark may indicate compliance

with other relevant EC directives. Consult the manufacturers EC Declarations of Conformity for details.

In addition to certified intrinsically safe apparatus, Veeder-Root also provides simple apparatus that comply with

the requirements of EN 60079-11, Clause 5.7. These devices include; Thermoprobe, Emergency Stop Switch,

Corner Switch and the Optional Keypad. Figures showing these devices may contain devices that are outside the

scope of this ATEX Certificate.

EMR4 System Specifications

COMPONENT LOCATION

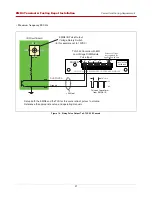

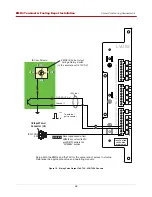

The EMR4 system should be located on a fuel delivery vehicle as shown in Figure 1 on page 3 or in a fueling

depot as shown in Figure 13 on page 20.

The equipment is designed to operate safely under the following range of conditions:

• Altitude up to 2000m.

• Temperature range - see Table A-1.

• A maximum relative humidity of 95% RH (non-condensing) at temperatures shown in Table A-1.

• A supply voltage fluctuation not exceeding 28 Vdc.

• Pollution Degree Category 2, Installation Category II.

• Vibration: MIL-STD-810G, Method 514.6; Table 514.6 C-VI Category 4

• Shock: MIL-STD-810G, Method 516.6; 20G, 11ms, 1/2-Sine

EMR4 IB units are not suitable for external locations and must be installed within the

interior of buildings or the cab of the fuel delivery vehicle.

Ensure that the

EMR4 IB

is located where neither the unit itself nor its associated cabling will be damaged by

doors, furniture, barrows, etc. - depot installs or nearby equipment - vehicle installs.

I

Category 1: suitable for installation in Zone 0, Zone 1 or Zone 2 hazardous areas

G

For potentially hazardous areas characterised by the presence of gases, vapours or mists

c

1180

Equipment marking is compliant with requirements in the CE Marking Directive.

NOTICE