Scanning Tunneling Microscopy (STM)

Troubleshooting for STM

Rev. B

MultiMode SPM Instruction Manual

155

9.4

Troubleshooting for STM

This section addresses errors or malfunctions encountered during the operation of the MultiMode

as an STM. See

in this manual for additional troubleshooting tips.

9.4.1 Head and Microscope-related Problems

This section deals with problems related to the scanners or the microscope. If a problem exists with

a scanner, try a second one under the same conditions, if possible. Otherwise, the following list of

symptoms and cures may be helpful:

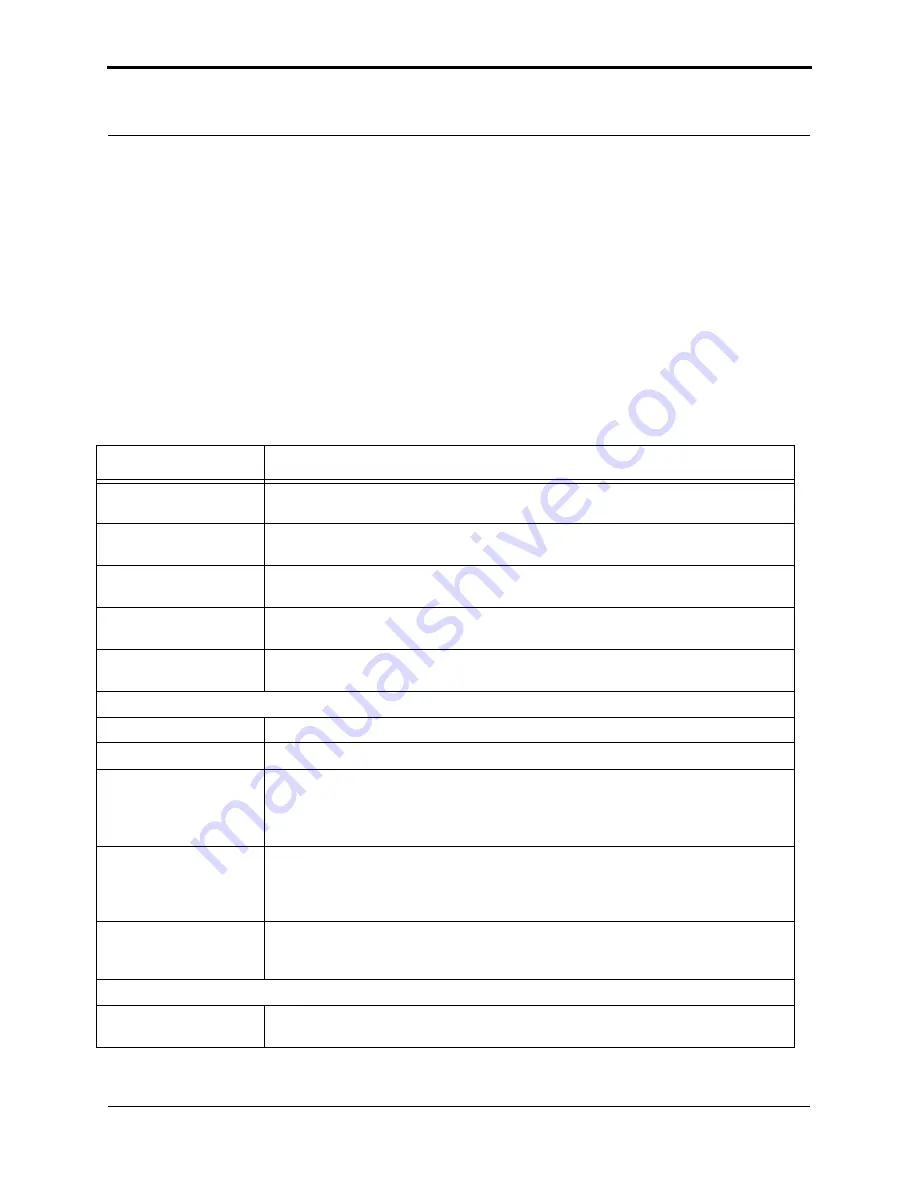

Table 9.4a

Head and Microscope Troubleshooting

Head/Tip Problem

Troubleshooting Tip

Head Engages

Immediately

If the STM engages immediately after initiating the

Motor

>

Engage

command, then one of the

following probably occurred:

Tip on surface

Make sure the tip is not touching the surface of the sample. Adjust the coarse-adjustment screws

upward until the tip is far from the surface.

Controller off

Verify that power to the controller is on and that the controller is connected to the computer

workstation via the beige 25-pin cable.

MultiMode base switch not

set for

STM

Verify that the switch on the left side of the MultiMode base is toggled to

STM

.

Disconnected

Verify that the 15-pin microconnector from the head is plugged into the microscope and the

microscope is plugged into the controller.

Tip Never Engages

If the tip never engages, test for the following:

Disconnected

Make sure the microscope is connected to the controller.

Binding on drive screw

Feel the rear, motor-driven adjustment screw during engagement to verify that it is rotating. If

the motion is erratic, then the screw is fouled with debris and binding. Remove the screw, clean

threads and regrease per instructions provided in

Vertical Engagement Scanners—Installa-

Bias shorted

Measure the bias by using a voltmeter between the head and stage chuck. If this is not in agree-

ment with the settings in the

Bias

voltage item in the STM Parameter control panel and appears

to be grounded, then check to see if anything is providing a conduction path between the Base

and the Base Support or any other ground.

Bias not applied to sample

surface

In some cases the sample consists of a layer of electrically conductive material on top of an insu-

lator. A conduction path must be provided between the sample puck and the sample surface.

Carbon glue or silver epoxy can be used to connect the bias voltage to the sample surface.

Tip Crashes

If the tip always crashes into the surface with the

Z Center Position

either changing erratically

or stuck in the fully retracted position, try the following: