relatively negative multiplier. In addition to allowing the detection of both positive

and negative ions, the off axis conversion dynode eliminates detection of photons

that would be seen by an on axis detector.

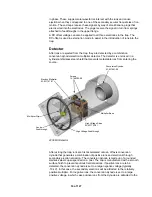

The continuous-dynode electron multiplier consists of a lead-oxide/glass, funnel-

like resistor. A negative voltage of between -800 and -3000V is applied to the

front end of the electron multiplier, referred to as the cathode. The back end of

the cathode is held near ground potential, and is referred to as the anode.

Electrons or ions emitted from the conversion dynode strike the cathode with

sufficient velocity to dislodge additional electrons from the inner curving surface

of the cathode. The increasingly positive potential gradient draws the ejected

electrons into the electron multiplier, further accelerating them in the process.

Because the electron multiplier is curved, the ejected electrons do not travel far

before they again strike the inner surface of the multiplier, resulting in the

emission of more electrons. This configuration produces a cascade of electrons

that is accelerated toward ground potential at the exit end of the cathode.

The anode collects the electrons and passes the resulting ion signal to the ion

amplifier that is mounted on the side of the vacuum manifold directly next to the

multiplier. The ion current is proportional to the total number of ions that the ion

trap ejects. Typically, the voltage applied to the electron multiplier should be

adjusted until the gain is about 10

5

, i.e., until each electron or positive ion that

enters the electron multiplier generates approximately 10

5

electrons.

Vacuum System

The analyzer is contained in a vacuum manifold maintained at a pressure of

10 µTorr. A turbomolecular pump provides the vacuum required. The turbo pump

is backed by a mechanical rotary foreline pump, which also performs the initial

evacuation of the vacuum manifold during pump down. A thermocouple gauge is

used to measure the foreline pressure and an ion gauge to measure the vacuum

manifold pressure.

Vacuum Manifold

The analyzer is contained in a nickel-plated aluminum vacuum manifold that

provides feedthroughs for the various electrical and pneumatic lines that are

required. A top flange feeds the end cap voltages and supplies all the source

electrical connections by way of a printed circuit board feedthrough. A front

flange feeds the CI and Calibration gases and supports the CI ion source

switching mechanism. A side flange provides multiplier connections. All three

flanges are sealed by Viton® O-rings. The manifold has line voltage heaters in its

base to provide heat for bake-out. Insulating material surrounds the manifold to

retain the heat. The turbomolecular pump is mounted horizontally to the rear of

the manifold.

Foreline Pump

The foreline pump has two purposes. The first is reducing the vacuum system

pressure to a level that will allow the operation of the high vacuum

turbomolecular pump. The second is maintaining the vacuum system pressure by

removing the turbomolecular pump’s exhaust gases.

The foreline pump is connected to the turbomolecular pump by a 2.1m (84 in.)

length of 1.9 cm (0.75 in.) ID vacuum tubing. The pump plugs into the rear panel

17 of 127

Summary of Contents for 4000 GC

Page 4: ......

Page 40: ...6 of 127...

Page 77: ...3 Check source connection pins for proper alignment and straighten as necessary 43 of 127...

Page 124: ...90 of 127...

Page 148: ...114 of 127...