TS

−

I Special servo drive for hybrid electro-hydraulic system of injection molding machine User Manual

16

Chapter 2 Installation and connection of servo driver

should be installed if the motor cable is longer than 100m. Refer to the following table for the carrier

frequency setting.

Length of cable between the

driver and motor

Less than 50m

Less than 100 m

More than 100m

Carrier frequency (PA.00)

Less than 15kHz

Less than 10kHz

Less than 5kHz

2.8.3 Grounding Wiring

The drive will produce leakage current. The higher the carrier frequency is, the larger the leakage

current will be. The leakage current of the driver system is more than 3.5mA, and the specific value of the

leakage current is determined by the application conditions. To ensure the safety, the driver and the motor

must be grounded.

The grounding resistance shall be less than 10ohm. For the grounding wire diameter requirement,

refer to 3.3 Models of main circuit peripheral devices.

Do not share grounding wire with the welding machine and other power equipment.

In the applications with more than 2 drivers, keep the grounding wire from forming a loop.

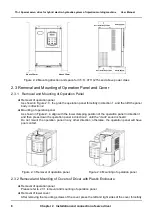

Correct Wrong

Figure 2

−

14 Grounding wiring

2.8.4 Countermeasures for Conduction and Radiation Interference

图

2

−

16

噪声电流图例

Figure 2

−

15 Noise current illustration

When the input noise filter is installed, the wire connecting the filter to the driver input power terminals

shall be as short as possible.

The filter enclosure and mounting cabinet shall be reliably connected in large area to reduce the back

flow impedance of the noise current Ig.

The wire connecting the driver and the motor shall be as short as possible. The motor cable adopts

4-core cable, with the grounding end grounded at the driver side, the other end connected to the motor

enclosure. The motor cable shall be sleeved into the metal tube.

Input filter

Inverter

Filtering cable

Input filter

Inverter

Filtering cable

Summary of Contents for TS-I Series

Page 1: ...User Manual TS I series servo drive is introdution V T ...

Page 2: ......