0020213394_05 Installation and maintenance instructions

33

11.3

Querying the fault memory

Menu

→

Installer level Fault list

The product has a fault memory. You can use this to query

the last ten faults that occurred in chronological order.

If a DCF sensor is connected, the date on which the fault

occurred will also be displayed.

Display views

–

Number of faults that occurred

–

The fault currently selected with fault number

F.xxx

11.4

Resetting the fault memory

1.

Press

(

Delete

).

2.

Confirm that you wish to clear the fault memory by

pressing

(

Ok

).

11.5

Restarting the installation assistant

You can restart the installation assistant any time by calling it

up manually in the menu.

Menu

→

Installer level

→

Start inst. assistant

11.6

Using check programmes

Menu

→

Installer level

→

Test menu

→

Check pro-

grammes

You can use this function to start check programmes.

Note

If a fault has occurred, the check programmes are

not run.

You can terminate the check programmes by pressing

(

Cancel

) at any time.

11.7

Carrying out the actuator test

Menu

→

Installer level

→

Test menu

→

Sensor/actuator

test

You can check that the components of the heating installa-

tion are functioning correctly using the sensor/actuator test.

You can actuate more than one actuator at a time.

If you do not select anything to change, you can have the

current control values for the actuators and the sensor val-

ues displayed.

You can find a list of the sensor characteristic values in the

appendix.

Characteristic values, external cylinder temperature sensor

(

Characteristic values, internal temperature sensors

(refrigerant circuit) (

Characteristic values for the VRC DCF outdoor temperature

sensor (

11.8

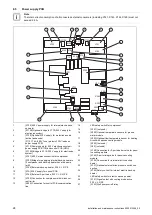

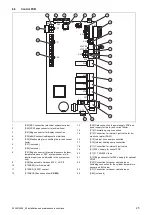

Electric back-up heater circuit breaker

A circuit breaker is used to secure the internal electric back-

up heater against short circuits. If the circuit breaker has

been triggered, the electric back-up heater remains switched

off until the short circuit has been eliminated and the circuit

breaker in the electronics box has been manually reset.

11.8.1 Resetting the circuit breaker in the electric

back-up heater

1.

Check the supply line to the power supply PCB.

2.

Check that the power supply PCB is working correctly.

3.

Check the connection cables for the electric back-up

heater.

4.

Check that the electric back-up heater is working cor-

rectly.

5.

Eliminate the short circuit.

6.

Reset the circuit breaker in the electronics box.

12 Inspection and maintenance

12.1

Inspection and maintenance information

12.1.1 Inspection

The inspection is intended to determine the actual condition

of a product and compare it with the target condition. This is

done by measuring, checking and observing.

12.1.2 Maintenance

Maintenance is required in order to eliminate any deviations

between the actual condition and the target condition. This is

normally done by cleaning, setting and, if necessary, repla-

cing individual components that are subject to wear.

12.2

Procuring spare parts

The original components of the product were also certified

by the manufacturer as part of the declaration of conformity.

If you use other, non-certified or unauthorised parts during

maintenance or repair work, this may result in the product no

longer meeting the applicable standards, thereby voiding the

conformity of the product.

We strongly recommend that you use original spare parts

from the manufacturer as this guarantees fault-free and safe

operation of the product. To receive information about the

available original spare parts, contact the contact address

provided on the back page of these instructions.

▶

If you require spare parts for maintenance or repair

work, use only the spare parts that are permitted for the

product.