32

Installation and maintenance instructions ecoTEC sustain 0020253094_05

Note

The actual reading on the digital pressure

gauge should ideally be 0,05 MPa (0,5 bar)

plus an additional pressure corresponding

to the highest point of the system above the

base of the boiler

–

10 m head equals an ad-

ditional 1 bar reading on the pressure gauge.

The minimum pressure should not be less

than 0,1 MPa (1 bar) in any installation. If

the system is to be treated with an inhibitor it

should be applied at this stage in accordance

with the manufacturer’s instructions

8.

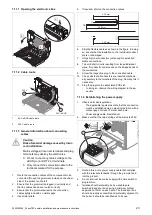

Install the front casing.

9.11

Checking leak-tightness

▶

Check the gas pipe, the heating circuit and the hot water

circuit for leak-tightness.

▶

Check that the flue system has been installed correctly.

9.11.1 Checking the heating mode

1.

Activate the heating mode on the user interface.

2.

Turn all thermostatic valves on the radiators until they

are fully open.

3.

Allow the product to operate for at least 15 minutes.

4.

Fill and purge the heating installation. (

5.

Call up the status codes. (

Status codes

–

Overview (

◁

If the product is working correctly, the display shows

S.04.

9.11.2 Checking the hot water generation

1.

Activate the hot water handling mode on the user

interface.

2.

Open a hot water valve completely.

3.

Call up the status codes. (

Status codes

–

Overview (

◁

If the product is working correctly, the display shows

S.14.

10 Adapting the unit to the heating

installation

10.1

Activating diagnostics codes

You can find the setting options in the diagnostics codes in

the installer level.

▶

Set a diagnostics code. (

10.2

Burner anti-cycling time

To prevent frequent switching on and off of the burner and

thus prevent energy losses, an electronic restart lockout

is activated for a specific period each time the burner is

switched off. The burner anti-cycling time is only active for

the heating mode. Switching on domestic hot water mode

during the burner anti-cycling time has no effect.

10.2.1 Setting the maximum burner anti-cycling

time

1.

Set a diagnostics code. (

T

Flow

(tar-

get)

[°C]

Set maximum burner anti-cycling time [min]

1

5

10

15

20

25

30

30

2.0

4.0

8.5

12.5

16.5

20.5

25.0

35

2.0

4.0

7.5

11.0

15.0

18.5

22.0

40

2.0

3.5

6.5

10.0

13.0

16.5

19.5

45

2.0

3.0

6.0

8.5

11.5

14.0

17.0

50

2.0

3.0

5.0

7.5

9.5

12.0

14.0

55

2.0

2.5

4.5

6.0

8.0

10.0

11.5

60

2.0

2.0

3.5

5.0

6.0

7.5

9.0

65

2.0

1.5

2.5

3.5

4.5

5.5

6.5

70

2.0

1.5

2.0

2.5

2.5

3.0

3.5

75

2.0

1.0

1.0

1.0

1.0

1.0

1.0

T

Flow

(target)

[°C]

Set maximum burner anti-cycling time

[min]

35

40

45

50

55

60

30

29.0

33.0

37.0

41.0

45.0

49.5

35

25.5

29.5

33.0

36.5

40.5

44.0

40

22.5

26.0

29.0

32.0

35.5

38.5

45

19.5

22.5

25.0

27.5

30.5

33.0

50

16.5

18.5

21.0

23.5

25.5

28.0

55

13.5

15.0

17.0

19.0

20.5

22.5

60

10.5

11.5

13.0

14.5

15.5

17.0

65

7.0

8.0

9.0

10.0

11.0

11.5

70

4.0

4.5

5.0

5.5

6.0

6.5

75

1.0

1.0

1.0

1.0

1.0

1.0

2.

If required, adjust the maximum burner anti-cycling time

using diagnostics code d.02.

10.2.2 Resetting the remaining burner anti-cycling

time

▶

Press and hold the

button for more than three

seconds.

◁

All symbols are shown in the display.

Summary of Contents for ecoTEC sustain 24

Page 1: ...en Installation and maintenance instructions ecoTEC sustain 24 28 34 0020253094_05 04 11 2020...

Page 61: ......

Page 62: ......

Page 63: ......