76

Installation and maintenance instructions 0020297933_07

7.11

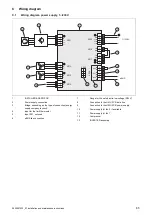

Connecting a limit thermostat

Condition

: No intermediate heat exchanger is installed in the indoor unit

▶

Use a 2-pole cable with a conductor cross-section of at

least 0.75 mm

²

.

▶

Route the cable from the building and through the wall

duct to the product.

S20

S21

BUS

5

6

3

4

1

2

X206

▶

Remove the bridge from the

X206, S20

connection. Con-

nect the cable here.

▶

Use the strain relief clamp to secure the cable in place.

Condition

: Intermediate heat exchanger installed in the indoor unit

▶

Connect the limit thermostat to the indoor unit (

→

Installa-

tion instructions about the indoor unit).

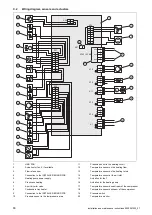

7.12

Connecting accessories

▶

Observe the wiring diagram in the appendix.

7.13

Installing the cover for the electrical

connections

1.

Note that the cover contains a safety-relevant seal

which must be effective in the case of a leak in the

refrigerant circuit.

2.

Secure the cover by lowering it into the stop on the

lower edge.

3.

Use two screws to secure the cover to the upper edge.

8

Start-up

8.1

Checking before switching on

▶

Check whether all the hydraulic connections are estab-

lished correctly.

▶

Check whether all the electrical connections are estab-

lished correctly.

▶

Check, depending on the type of connection, whether

one or two disconnectors are installed.

▶

If it is stipulated for the installation site, check whether a

residual-current circuit breaker has been installed.

▶

Read through the operating instructions.

▶

After installation, ensure that at least 30 minutes have

passed before switching on the product.

▶

Ensure that the cover for the electrical connections is

installed.

8.2

Switching on the product

▶

Switch on all of the disconnectors to which the product is

connected in the building.

8.3

Checking and treating the heating

water/filling and supplementary water

Caution.

Risk of material damage due to poor-qual-

ity heating water

▶

Ensure that the heating water is of suffi-

cient quality.

▶

Before filling or topping up the installation, check the

quality of the heating water.

Checking the quality of the heating water

▶

Remove a little water from the heating circuit.

▶

Check the appearance of the heating water.

▶

If you ascertain that it contains sedimentary materials,

you must desludge the installation.

▶

Use a magnetic rod to check whether it contains mag-

netite (iron oxide).

▶

If you ascertain that it contains magnetite, clean the in-

stallation and apply suitable corrosion-inhibition meas-

ures (e.g. fit a magnetite separator).

▶

Check the pH value of the removed water at 25 °C.

▶

If the value is below 8.2 or above 10.0, clean the installa-

tion and treat the heating water.

▶

Ensure that oxygen cannot get into the heating water.

Checking the filling and supplementary water

▶

Before filling the installation, measure the hardness of the

filling and supplementary water.

Treating the filling and supplementary water

▶

Observe all applicable national regulations and technical

rules when treating the filling and supplementary water.

Provided the national regulations and technical rules do not

stipulate more stringent requirements, the following applies:

You must treat the heating water in the following cases

–

If the entire filling and supplementary water quantity dur-

ing the operating life of the system exceeds three times

the nominal volume of the heating installation, or

–

If the guideline values listed in the following table are not

met, or

–

If the pH value of the heating water is less than 8.2 or

more than 10.0.

Validity:

Denmark OR Sweden

Total

heating

output

Water hardness at specific system volume

1)

≤

20 l/kW

> 20 l/kW

≤

40 l/kW

> 40 l/kW

kW

°dH

mol/

m

³

°dH

mol/

m

³

°dH

mol/m

³

< 50

≤

16.8

2)

≤

3

2)

≤

8.4

3)

≤

1.5

3)

< 0.3

< 0.05

> 50

to

≤

200

≤

11.2

≤

2

≤

5.6

≤

1.0

< 0.3

< 0.05

> 200

to

≤

600

≤

8.4

≤

1.5

< 0.3

< 0.05

< 0.3

< 0.05

> 600

< 0.3

< 0.05

< 0.3

< 0.05

< 0.3

< 0.05