74

Installation and maintenance instructions 0020297933_07

7.1

Preparing the electrical installation

Danger!

Risk of death from electric shock as a res-

ult of an improper electrical connection!

An improper electrical connection may neg-

atively affect the operational safety of the

product and result in material damage or per-

sonal injury.

▶

Only carry out the electrical installation if

you are a trained competent person and

are qualified for this work.

1.

Observe the technical connection conditions for con-

necting to the energy supply company's low-voltage

network.

2.

Determine whether the energy supply company lockout

function has been provided for the product, and how

the power supply for the product should be designed,

depending on the type of shutdown.

3.

Use the data plate to determine the product's rated

current. Derive the suitable cable cross-sections for

the electrical wires from this.

4.

Prepare the routing of the electrical wires from the

building and through the wall duct to the product. If the

line length exceeds 10 m, prepare the separated rout-

ing of the power supply cable and sensor/bus line.

7.2

Requirements for the quality of the mains

voltage

For the mains voltage of the single-phase 230 V network, a

tolerance of +10% to -15% must be provided.

7.3

Requirements for electrical components

Flexible hose lines that are suitable for routing outdoors must

be used for the power supply. The specification must com-

ply with the standard 60245 IEC 57 with the abbreviation

H05RN-F as a minimum.

The electrical partitions must have a contact gap of at least

3 mm.

For the electrical fuse protection, slow-blow fuses with C

characteristics must be used.

To protect people, type B universal-current-sensitive resid-

ual-current circuit breakers must be used if these are stipu-

lated for the installation site.

7.4

Requirements for the eBUS line

Observe the following rules when routing the eBUS lines:

▶

Use twin-core cables.

▶

Never use shielded or twisted cables.

▶

Use only appropriate cables, e.g. NYM or H05VV (-F/-U).

▶

Observe the permissible total length of 125 m. For a

total length of up to 50 m, a conductor cross-section of

≥

0.75 mm

²

applies; from 50 m upwards, a conductor

cross-section of 1.5 mm

²

applies.

In order to prevent faults in the eBUS signals (e.g. due to

interferences):

▶

Maintain a minimum clearance of 120 mm to power sup-

ply cables or other electromagnetic sources of interfer-

ence.

▶

For parallel routing to mains connection lines, guide the

cables in accordance with the applicable regulations, e.g.

on cable trays.

▶

Exceptions:

For wall breaks and in the electronics box, it

is acceptable to not reach the minimum clearance.

7.5

Electrical partition

The electrical partition is also referred to as a "disconnector"

in these instructions. The fuse or the circuit breaker that is

installed in the building's meter/fuse box is usually used as

the disconnector.

7.6

Installing components for the energy supply

company lockout function

With the energy supply company lockout function, the heat

generation from the heat pump can be switched off tempor-

arily by the energy supply company. The unit can be shut

down in two ways:

1.

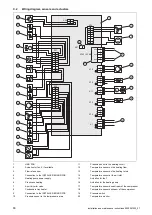

The signal for the shutdown is fed to connection S21

for the indoor unit.

2.

The signal for the shutdown is fed to a partition that is

installed on-site in the meter/fuse box.

▶

If the energy supply company lockout function is

provided, install and wire additional components in the

building's meter/fuse box.

▶

To do this, follow the wiring diagram in the appendix of

the installation instructions for the indoor unit.

7.7

Removing the cover for the electrical

connections

B

A

1.

Note that the cover contains a safety-relevant seal

which must be effective in the case of a leak in the

refrigerant circuit.

2.

Remove the cover, as shown in the figure, without

damaging the circumferential seal.