vacon • 14

Filter types

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

2.2

dU/dt filters

2.2.1

General

The VACON

®

NX drives use IGBT transistors as an output element. These semiconductors create

the correct voltage to the motor switching it at very high speed (4 - 6 kV/s) with an unloaded IGBT.

This high speed will, under certain circumstances, cause extra voltage stress on the main insulation

of the motor.

Usually there are no problems with motors designed for a 400 V supply. Such motors are usually

designed for a voltage level of 1200 V, which exceeds the AC drive induced stress.

In 500 V supplies the motor has to withstand at least 1600 V. A dU/dt filter is often required with

these motors in order not to exceed the allowable voltage stress. In 690 V supplies the motor has to

withstand at least 1800 V, and a dU/dt filter is required in these cases.

NOTE!

In uncertain cases, confirm the rating of the motor in AC drive application with the motor

manufacturer.

NOTE!

Set the switching frequency parameter to correspond to the value printed on the nameplate

of the filter and the output voltage level. Do not increase the switching frequency above the rated

value of the filter. Decreasing it below is allowed.

The high switching speed (about 2 kV/s) with the motor and cable connected, creates a travelling

wave in the cable. The speed of this wave is set by the cable's wave impedance, usually about 50 -

100 Ω. This is less than the motor's wave impedance, which is on the order of 1 kΩ. As the travelling

voltage wave hits this discontinuity, it is reflected back, increasing the instantaneous voltage on the

motor winding. The wave is reflected back and forth between motor and drive and finally the steady

state voltage is reached.

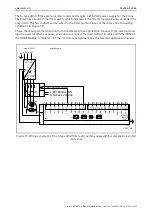

Winding voltage stresses

The rapid change in voltage is not distributed equally over all windings, but the first windings show

higher voltage stresses than the inner ones, due to the capacitive coupling between the windings.

Modern motors can withstand a voltage rise times of < 2 kV/µs. In case of doubt, use a dU/dt filter

or contact the motor manufacturer.

Figure 5. Change of the voltage shape in winding

#

Reference

#

Reference

A

Incoming pulse

B

Winding voltage

B

A

7122_00