Vision™ OPLC™

Unitronics

9

Communication Port

Turn off power before making communications connections.

Caution

Signals are related to the controller’s 0V; the same 0V is used by the power supply.

Always use the appropriate port adapters.

The serial port is not isolated. If the controller is used with a non-isolated external

device, avoid potential voltage that exceeds ± 10V.

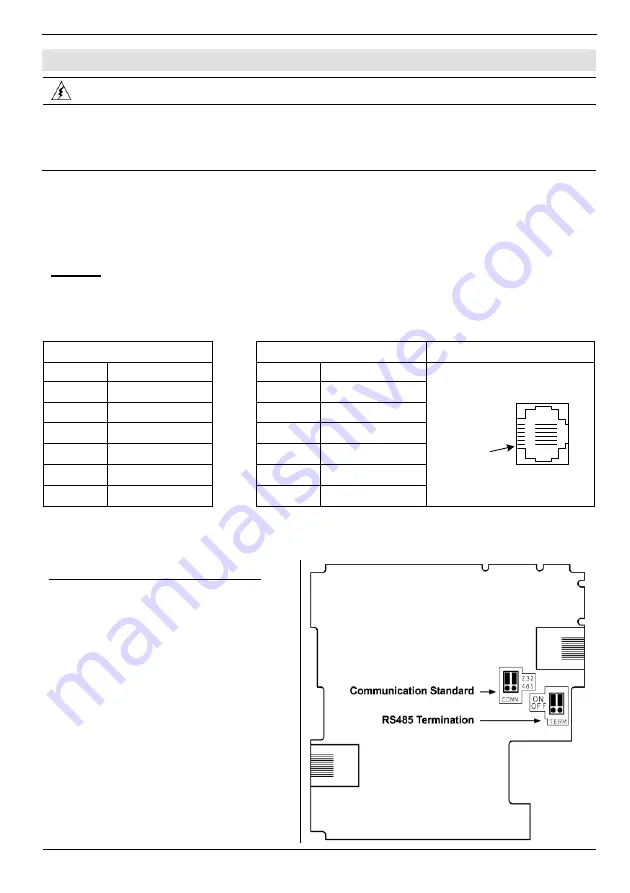

Port 1 is type RJ-11 and may be set to either RS232 or RS485 via jumper as shown below.

By factory default, the port is set to RS232, termination ON.

Use RS232 to download programs from a PC, and to communicate with serial devices

and applications, such as SCADA.

Use RS485 to create a multi-drop network containing up to 32 devices.

Pinouts

The pinouts below show the PLC port signals.

To connect a PC to a port that is set to RS485, remove the RS485 connector, and connect the PC to

the PLC via the programming cable. Note that this is possible only if flow control signals are not used

(which is the standard case).

RS232

RS485**

Controller

Port

Pin #

Description

Pin #

Description

1* DTR

signal

1

A signal (+)

2

0V reference

2

(RS232 signal)

3

TXD signal

3

(RS232 signal)

4

RXD signal

4

(RS232 signal)

5

0V reference

5

(RS232 signal)

6* DSR

signal

6

B signal (-)

Pin #1

*Standard programming cables do not provide connection points for pins 1 and 6.

**When a port is adapted to RS485, Pin 1 (DTR) is used for signal A,

and Pin 6 (DSR) signal is used for signal B.

RS232 to RS485 Jumper Settings

The figure to the right shows the jumper

factory default settings, RS232, RS485

termination ON.

Note that in order:

To change the communication

setting to RS485, both

communication standard jumpers

must be moved

To change the RS485

termination, both termination

jumpers must be moved

To access the jumpers, you must open the

controller according to the instructions

beginning on page 10.