35

4

Calibration

35

Calibr

a

ti

on

Chapter

4

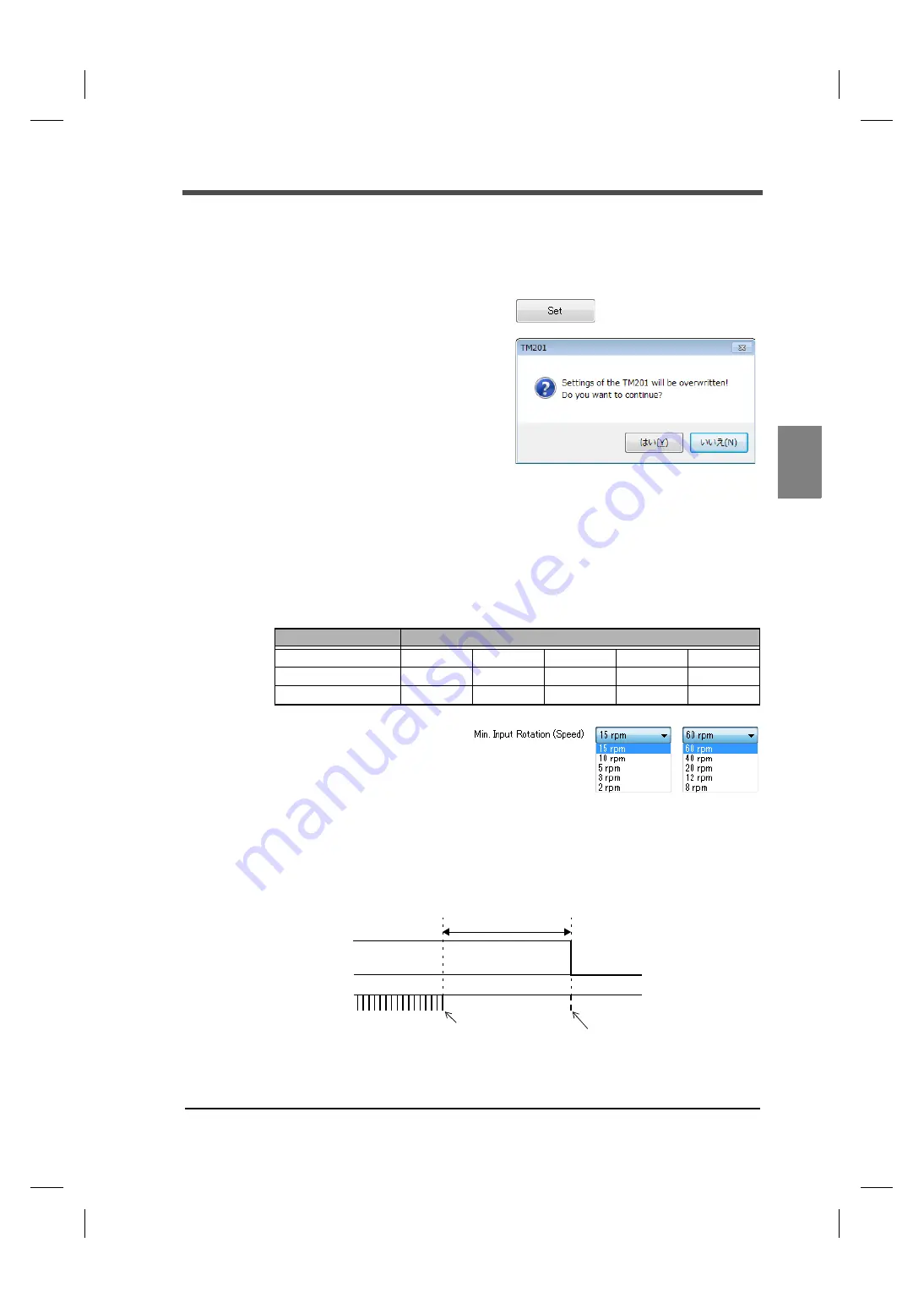

(6) Calibration setting is written to the TM201.

The values selected in (1) to (5) are written to the TM201.

■

Execution procedure

1.

Click the "Set" button.

2.

When the "Set" button is clicked, a

confirmation dialog to overwrite is

displayed, and click "Yes (Y)".

4-5.

Rotation stop settings for rotation speed

Minimum input rotation speed

Minimum input rotation speed that can be displayed is selectable.

≪

Setting value

≫

Example) When set at "2rpm"

Since waiting for pulse detection for the duration of maximum detection time is required when

rotation stops suddenly from high speed state, the previous rotation speed is not updated;

therefore, the display will become 0 rpm after the display of the rotation speed that was last

detected has held for 7.5 seconds.

Pulse rate

Minimum input rotation speed (frequency)

4 pulses

15 rpm

10 rpm

5 rpm

3 rpm

2 rpm

1 pulse

60 rpm

40 rpm

20 rpm

12 rpm

8 rpm

Max. detection time

1 sec

1.5 sec

3 sec

5 sec

7.5 sec

Rotation stops suddenly

Pulse

Display

3000rpm

0rpm

7.5sec (Display held)

2 rpm pulse does not arrive