24

7

OPTION

24

OP

TION

Chapter

7

7-1.

BCD data output

The BCD data output interface is used to obtain the indicated value of the F331 as BCD data. It is

convenient for connecting the F331 with a computer, process controller, PLC, etc., to perform

processing, such as controlling, aggregating, and recording.

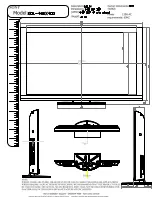

Assembling connector

1.

Align the connector and each screw (two) in the groove in one case.

2.

Put the other case on it, and fit the cases together.

3.

Tighten each M2×8 pan-head machine screw (two).

Tighten each M2×10 pan-head machine screw (two).

Be aware that the M2×10 pan-head machine screw should be combined

with a washer.

7

OPTION

A16

B16

A1

B1

Case (two)

Screw (two)

Connector

M2×10 pan-head machinescrew

M2 nut (four)

Washer (two)

(short) (two)

(long) (two)

M2×8 pan-head machine screw

Summary of Contents for F331

Page 1: ...OPERATION MANUAL 26MAY2014REV 1 02 DIGITAL INDICATOR F331 ...

Page 79: ...70 8 SPECIFICATIONS 70 SPECIFICATIONS Chapter 8 8 2 Dimensions Unit mm ...

Page 82: ...73 8 SPECIFICATIONS 73 SPECIFICATIONS Chapter 8 When the RS 485 option is equipped Unit mm ...

Page 83: ...74 8 SPECIFICATIONS 74 SPECIFICATIONS Chapter 8 When the RS 232C option is equipped Unit mm ...