17

ACCESSORIES, CONSUMABLES and OPTIONAL PARTS

EXTENDED WARRANTIES

For North American Customers

An extended warranty may be purchased within 3 months from the date of purchase.

There are two types of warranty:

1) parts

2) parts and labor

The warranty period is 2, 3 or 4 years.

If you would like to purchase an extended warranty call Uni-ram at:

Canada

1-800-417-9133

USA

1-800-735-4331

P

art No.

Description

110-430

Nozzle Adapter, Push On, Conventional Systems Only

110-430PPS

Nozzle Adapter, Push On, Disposable and Conventional Systems

780-3530

Nozzle Adapter, Disposable Cup Systems Only

100-413F

Paint

Cap

Holder

115-200/K

Mechanical

Timer

Assembly,

5

minutes

140-230 Air

Passage

Plug

140-2340

Trigger Clamp & Plug Kit

140-340S

Rotating

Spray

Jet

Assembly

144-390 Flow-Through

Brush

Assembly

144-397

Hose for Flow-Through Brush

100-835

Ground Wire for Gun Cleaner, 18G, Green, 4 FT

600-8901

Ground Wire for Pail

FP6000-10

Filter Pad, UG6000, Pkg of 10

FP6500-10

Filter Pad, UG4000, Pkg of 10

KIT-MW4000

Manual Wash Kit, Upgrade DV to DVM

780-8000

2-Pail Set, Plastic, Kit, including Hoses & Fittings (for connecting to

Solvent

Recyclers)

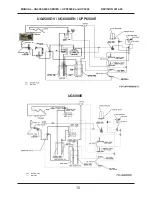

Pail Set, Part No. 780-8000

(hoses come with P2

Recycler (URS500P2,

URS600P2, URS900P2)

MANUAL - UG4000-6000 UPP6500E and UP6000

REVISION 2014-09