USER GUIDE

Drawers

u-line.com

Severe Adjustment:

Note:

The slides have extra mounting holes that may be

used.

1. Loosen one slide’s rear mounting screws.

2. Remove the slide’s front

mounting screws.

3. Reposition the slide so it is

level.

4. Mark new front drilling

holes using a different set

of mounting holes on the slide.

5. Drill the new holes with a #30 drill bit.

6. Remount the slide.

7. Repeat procedure for the other slide.

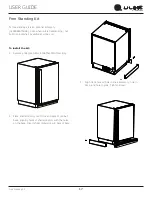

TOP-TO-BOTTOM (AND LEFT-TO-RIGHT)

ADJUSTMENT

The drawer will need a Top-to-Bottom Adjustment if, when

viewed from the front, the drawer is not level horizontally.

Viewed from the top, one side will protrude. This is caused

by one of the slides being mounted higher than the other

slide on the unit’s liner.

Minor Adjustment:

Note:

The mounting holes on the slide are slightly larger

than the screws’ diameter.

1. Loosen one slide’s mounting

screws.

2. Push the slide upward or

downward to match the

position of the other slide.

3. Retighten the screws.

4. Repeat the procedure with the other slide if necessary.

Severe Adjustment:

Note:

The slides have extra mounting holes that may be

used.

1. Remove one slide’s

mounting screws.

2. Reposition the slide so it is

the same distance from the

bottom of the liner as the

other slide. Measure to

confirm.

3. Mark new drilling holes using different sets of mounting

holes on the slide.

Note:

Front location holes are shown. Corresponding rear

holes will also need to be marked.

4. Drill all the new holes with a #30 drill bit.

5. Remount the slide.

Mark and Drill New

Mounting Holes

Level the Slide

Not Aligned Left-to-Right

Top View of Unit

Front View of Unit

Not Aligned

Top-to-Bottom

Push

Slide

Upward

or

Downward

Loosen

Mounting Screws

Mark and Drill New

Mounting Holes

Push Slide

Upward or

Downward

15