14

Appendix C Turnstile Control Board

1Communication Protocol Specifications

Could choose RS232, RS485 OR UDP interface to Communicate between

c

ontrol board & PC

1.1 Initialization & reading control board parameters

PC send communication demand [address(if you choose UDP interface, no need

a

0x02 0xFF 0x00 0x04

] to control board. Control board receive communication

demand and send feedback signal [address(if you choose UDP interface, no need

a

0x02 0xFF 0x00 0x04

] to PC, until PC send feedback signal [address(if you

choose UDP interface, no need a

0x02 0xFF 0x00 0x04

] or overtime (waiting

time is 2 seconds). The control board of turnstiles will send related parameters after

received feedback signal. Every parameter sent by main board needs the feedback

signal [address(if you choose UDP interface, no need a

0x02 0xFF 0x00 0x04

]

from PC, then send the next parameter. Or overtime (waiting time is 2 seconds).

Sending parameters as follows:

1) Equipment Model Number

2) Software Version Number

3) Equipment ID Number

4) Turnstile Working Mode

5) Working Mode of Entry & Exit

6) Door Closing Delay

7) Door Opening & Closing Speed (inapplicable to tripod turnstiles)

8) Entry Counting

9) Exit Counting

10) IR Sensors’ Sensitivity (inapplicable to tripod turnstiles)

For detailed corresponding command formats, please refer to 2. Control Board Sending

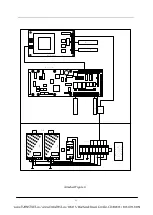

Command. Below is the flow Chart: