10

ADVANCED FEATURES ON THE STRAIGHT WASTEGATE

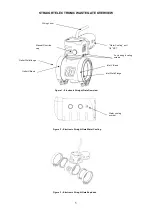

Water Cooling

Turbosmart’s Straight Gate is equipped with water cooling ports

to keep the wastegate cool in the most extreme conditions and

keep consistent actuator temperature.

Identify the water cooling ports on the bottom of the actuator

adjacent to the water-cooling symbol engraved in the actuator.

Figure 13

– Water Cooling Ports

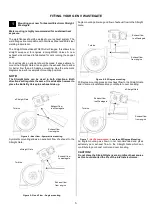

Fit water-cooling port fittings Prior to mounting the wastegate,

install 1/8” NPT fittings into the water ports, apply thread lubricant

and screw in clockwise until finger tight, then tighten further 1-2

turns for seal. Choose feed and drain source for the water and

connect to the wastegate. Turbosmart recommends -4SAE

fittings and hose compatible with coolant. It is

not

important

which way the water flows through housing.

CAUTION!

Check for leak, ensure the water-cooling circuit is free from

leaks.

Figure 14

– Water Lines

HOW TO CONDUCT MAINTENANCE ON YOUR ELECTRONIC STRAIGHT GATE

Basic Maintenance

The Straight gate will require periodic maintenance depending

on application. In high demand, unusually environments, it is

advisable to increase the service interval.

Turbosmart recommends that the internal gearbox is

regreased with a spray type grease such as Inox MX8 spray

grease this should be conducted half yearly or more

depending on environment. With the top plate removed grease

can be sprayed into the small inspection holes located near

the magnet.

Motor Replacement

In the event of the motor failing, it can be easily replaced. The

Motor Housing (figure 15) must be dissembled, the cap must

be removed with the Turbosmart rear housing tool, this opens

the rear of the motor housing, once open the motor wires will

need to be moved out of the way . The red wire is matched to

the red dot on the back of the motor cover. With the wiring

clear the 4mm Allen keys will need to be removed. The rear

housing will separate. Pulling it off the back. The replacement

motor part number (TS-0550-3123)

Figure 15

– Motor End Cap

Note! The red wire is matched to the red dot on the electric

motor.

A 2.5mm Allen key will be required to remove the motor

screws. With both undone. The motor can be lightly pushed

out. When reinstalling, use a small application of Loctite 243

Water cooling

Port (2 holes)

1

3

Water

cooling

symbol

Water

feed/return

1

2