6

Load Filament

The 3D printing of pellets is characterized by being a type of manufacturing different from the printing process with filament spools.

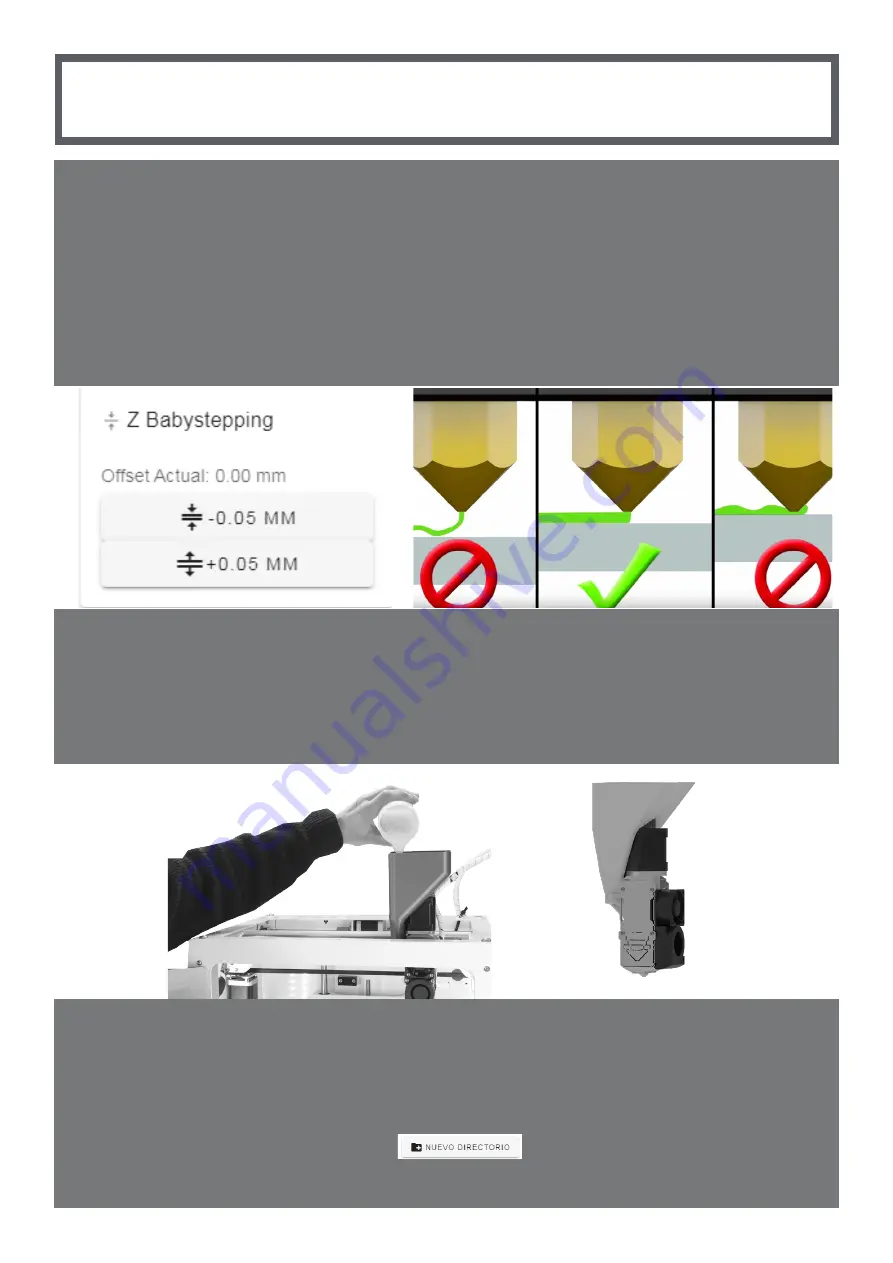

• First, introduce the pellets into the hopper manually.

• The pellets will begin to fall through the hopper and will melt inside the extruder.

• The molten material will be ejected from the nozzle and will begin to adhere to the build platform.

Level the Build Plate

• Heat the base to the temperature you want to print at

• Make sure you have a clean tip

• Execute the calibration process found in the Macros “Calibration” section and follow the steps

• Use the knurled nuts on the base to fit the Nozzle to the Build Base

• If it was your first calibration you may have to repeat this process

• During printing, fine-tune using Z Babystepping until proper adhesion is achieved

Load G-Code / Print

• In Jobs select:

UPLOAD FILE (S) TO G-CODE

and upload your “.gcode” file

• With the left button click on the file you want to print

• With the right button select more options

• You can create folders to organize your files by clicking