920.1020.12

31

ADJUSTING THE CHAIN TENSIONER

•

1. At the tensioner pivot point, loosen the lock nut at the Tensioner Adjustment.

•

2. At tensioner block, loosen the Allen-head screw (do not remove it).

•

3. Insert 4mm Allen wrench into the tensioner adjustment and apply tension counter

clockwise to increase tension on the chain.

•

4. Rotate chain tensioner lock plate clockwise so the plate is pressing against the back plate

•

5. Re-torque the tensioner block screw while maintaining chain tension - These bolts are

generally torqued to around 3.7ft lbs.

•

6. Re-tighten the lock nut at the pivot point.

•

7. When complete, double check physical stops for 0 and 90 degree door position - adjust if

necessary.

•

8. Launch a new setup at the control and ensure everything works ok. Any time the stroke

of the operator has changed, a new setup will be required.

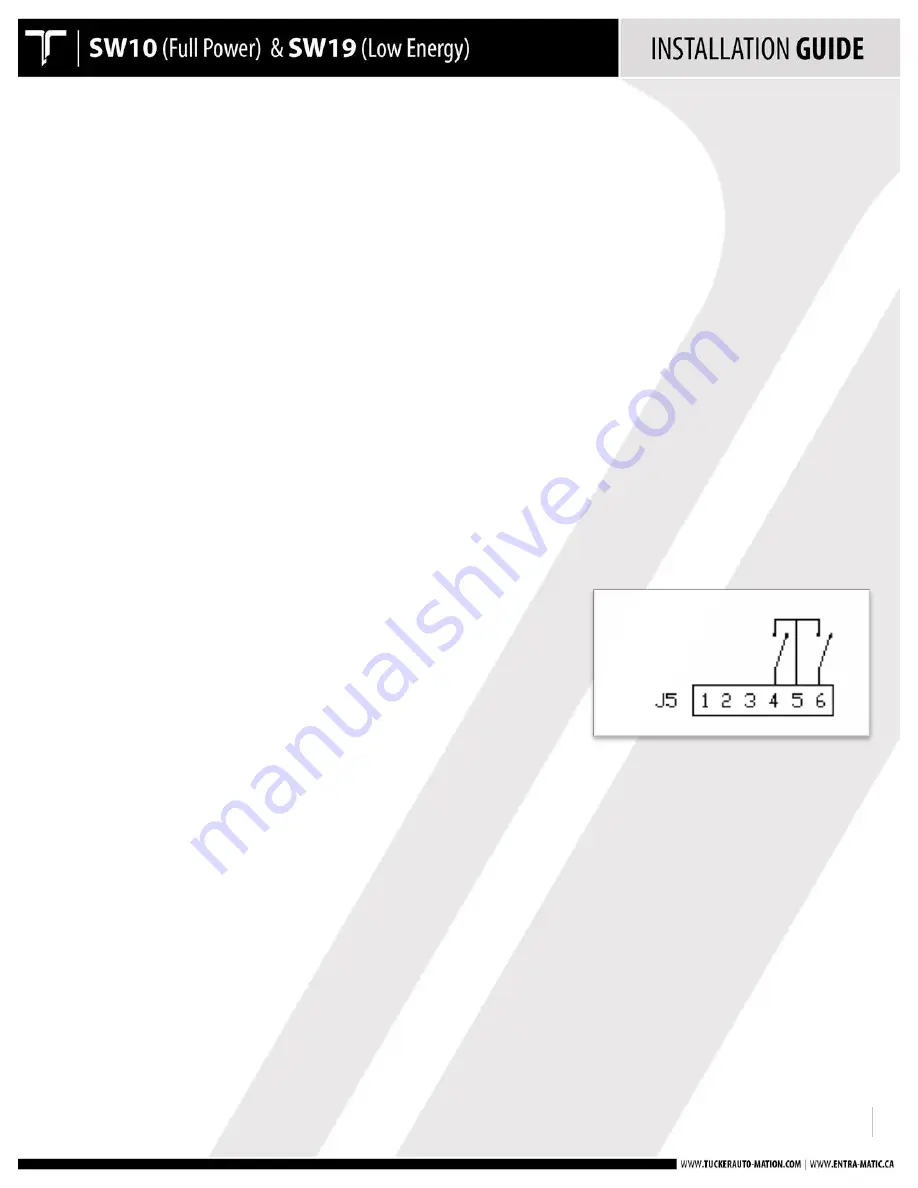

APPENDIX – WIRING DIAGRAMS

DOOR STATUS SWITCH

Terminal 4:

Door “Closed” status switch: Contact closes

upon full door closed position.

Terminal 5:

Common

Terminal 6:

Door “Open” status switch: Contact is closed

when door is full open.

Summary of Contents for SW10

Page 11: ...920 1020 12 11 PUSH ARM ...

Page 27: ...920 1020 12 27 SETUP BUTTON FLASHING RED LED ...

Page 33: ...920 1020 12 33 APPENDIX WIRING DIAGRAMS SIMULTANEOUS PAIRS ...

Page 35: ...920 1020 12 35 APPENDIX WIRING DIAGRAMS ELECTRIC LOCK APPLICATION ...

Page 36: ...920 1020 12 36 APPENDIX WIRING DIAGRAMS SW10 PAIR WITH BEA PARALLAX SYSTEM ...

Page 37: ...920 1020 12 37 APPENDIX WIRING DIAGRAMS SW10 Single Pair WIth BEA LZR Microscan Sensors ...