-9-

Before starting

(1) Make sure once again that the product is of the correct voltage and frequency rating.

Using the product at other than rated voltage and frequency will not only

lower its performance but may damage the product.

Conf rm the rated voltage and frequency on the model name plate.

(2) Confirm the wiring, supply voltage, circuit breaker capacity, and motor insulation resistance.

Reference insulation resistance = 20 MΩ or greater

The reference insulation resistance (20MΩ or greater ) is the value when the pump is new or has been

repaired. For the reference value after installation, see below at Maintenance and Inspection (p.11)

(3) The setting on the circuit breaker or other overload protector should be made in accord with the rated

currency of the pump.

See the model name plate on the pump for its rated current.

(4) When powering the pump with a generator, do not share the generator with other equipment.

CAUTION

Note:

Note:

Note:

6 OPERATION

(2) If the direction is reversed, correct it using the countermeasure shown below.

Before changing the connections to correct the rotation, be sure to turn off

the power supply (circuit breaker), and make sure the impeller has stopped

completely, to avoid electrical shock or shorting.

WARNING

Test operation

• Never operate the pump while it is suspended in the air. The recoil may

result in injury or other major accident.

• Never start the pump when people are standing next to it. An electrical leak

can result in electrical shock.

(1) Run the pump for a short time(1~2 seconds) to check the direction of rotation. The rotation is correct if

the pump recoil direction is counter-clockwise.

Always perform the rotation check in air, not while the pump is submersed.

Running the pump in reverse direction while submersed may damage the

pump, resulting in electrical leakage or electrical shock.

WARNING

CAUTION

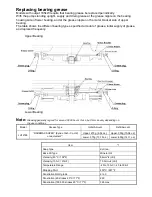

COUNTERMEASURE

Interchange connections between any two of

the three leads R, S, or T.

R S T

Example :

Interchanging

phases S and T

(3) Run the pump for a short time (3~10minutes) and confirm the following.

Using an ammeter(clamp-on type), measure the operating current at the U, V, and W phase leads on the

terminal strip.

COUNTERMEASURE

If the operating current exceeds the rated value, pump motor overload may be a cause. Make sure the pump

has been installed under proper conditions as described in the section on Installation(p.6)

Using an AC voltmeter(tester), measure voltage at the terminal strip.

Supply voltage tolerance: within ± 5% of rated voltage.

COUNTERMEASURE

If the supply voltage is outside the tolerance, possible causes are the power supply capacity or an inadequate

extension cable. Look again at Electrical Wiring(p.7) and make sure the conditions are proper.

In case of very excessive vibration, unusual noise or odor, turn off the power

immediately and consult with your nearest dealer or Tsurumi representative.

Continuing to operate the pump under abnormal conditions may result in

electrical shock, fire, or electrical leakage.

(4) If the test operation turns up no problems, continue with full operation.

CAUTION