21

4.

TROUBLESHOOTING

4.1 Common Problems

The following guide lists the most common problems that may be encountered when

operating this bar code printer. If the printer still does not function after all suggested

solutions have been invoked, please contact the Customer Service Department of

your purchased reseller or distributor for assistance.

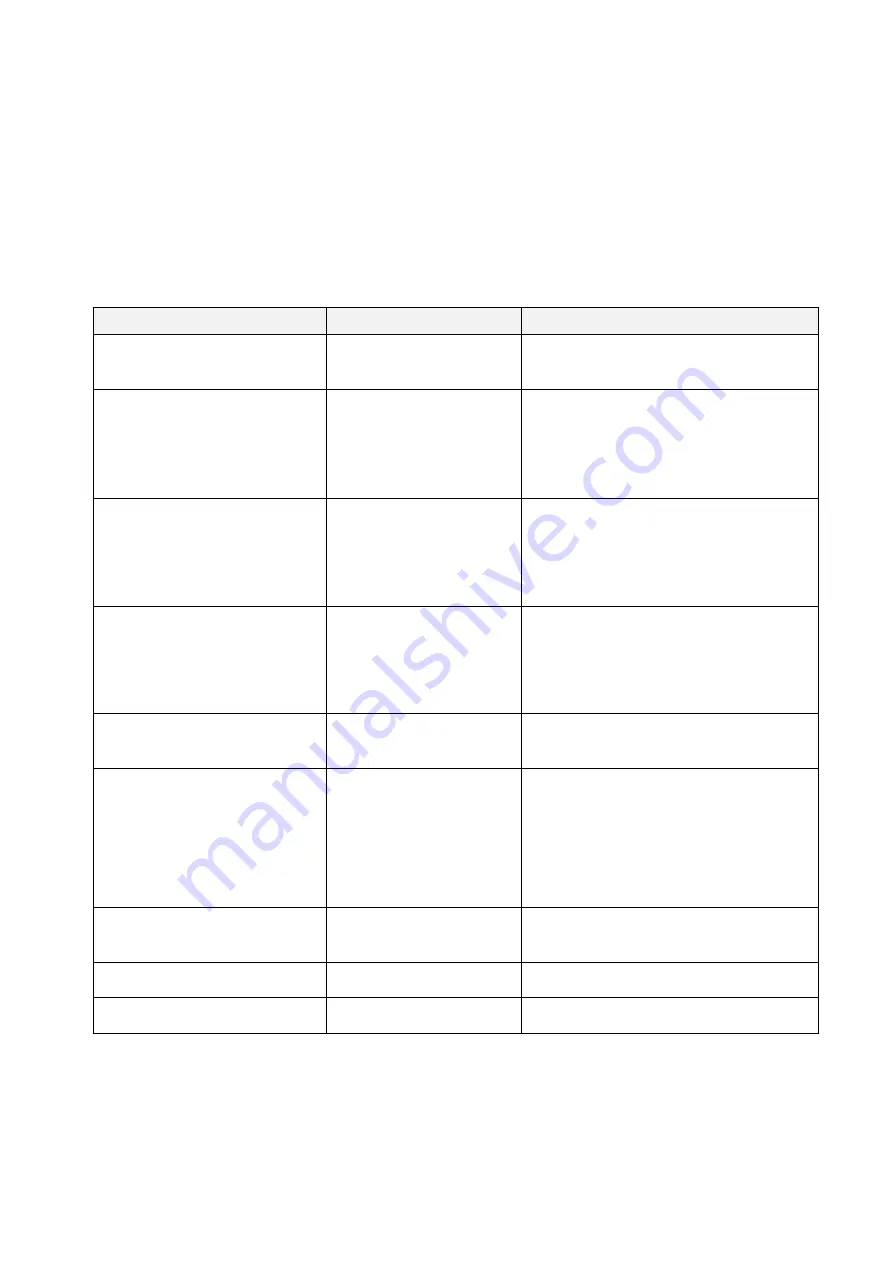

Problem

Possible Cause

Recovery Procedure

Power indicator does not

illuminate

* The battery is not properly

installed.

* The battery is dead.

* Reinstall the battery.

* Switch the printer on.

* Charge the battery.

The printer status from DiagTool

shows

“

Head Open

”.

* The printer carriage is

open.

* Please close the print carriage.

The printer status from DiagTool

shows

“

Out of Paper

”..

* Running out of media roll.

* The media is installed

incorrectly.

* Black mark sensor is not

calibrated.

* Supply a new media roll.

* Please refer to the section 3.4 on

User’s

manual to reinstall the media roll.

* Calibrate the black mark sensor.

The printer status from DiagTool

shows

“

Paper Jam

”.

* Black mark sensor is not

set properly.

* Make sure media size is

set properly.

* Media may be stuck inside

the printer mechanism.

* Calibrate the black mark sensor.

* Set media size correctly.

Memory full

( FLASH / DRAM )

* The space of

FLASH/DRAM is full.

* Delete unused files in the FLASH/DRAM.

Poor Print Quality

* Media is loaded incorrectly

* Dust or adhesive

accumulation on the print

head.

* Print density is not set

properly.

* Printhead element is

damaged.

* Reload the supply.

* Clean the print head.

* Clean the platen roller.

* Adjust the print density and print speed.

* Run printer self-test and check the print

head test pattern if there is dot missing in

the pattern.

* Change proper media roll.

Missing printing on the left or

right side of label

* Wrong label size setup.

* Set the correct label size.

Gray line on the blank label

* The print head is dirty.

* The platen roller is dirty.

* Clean the print head.

* Clean the platen roller.

Irregular printing

* The printer is in Hex Dump

mode.

* Turn off and on the printer to skip the

dump mode.