B -

23

Infrared Camera – Operating Manual

EN

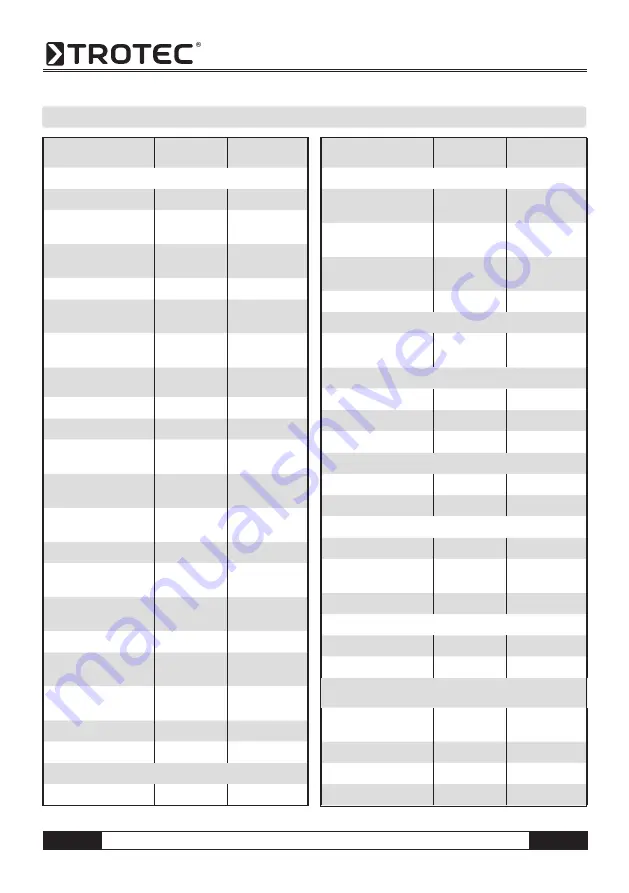

Material

Temperature

(°C)

Emissivity

(approx.)

Iron

Polished cast iron

200

0.21

Processed cast iron

20

0.44

Polished tempered

iron

40 ~ 250

0.28

Polished steel ingot

770 ~ 1040

0.52 ~ 0.56

Raw welded steel

945 ~ 1100

0.52 ~ 0.61

Surface ferric oxide

20

0.69

Completely rusty

surface

22

0.66

Rolled iron plate

100

0.74

Oxidized steel

198 ~ 600

0,64 ~ 0,78

Cast iron

(oxidised at 600°C)

198 ~ 600

0.79

Steel

(oxidised at 600°C )

125 ~ 520

0.78 ~ 0.82

Electrolytic ferric

oxide

500 ~ 1200

0.85 ~ 0.89

Iron plate

925 ~ 1120

0.87 ~ 0.95

Cast iron,

heavy ferric oxide

25

0.80

Tempered iron,

ferric oxide

40 ~ 250

0.95

Melting surface

22

0.94

Melting cast iron

1300 ~ 1400

0.29

Melting mild steel

1600 ~ 1800

0.28

Liquid steel

1500 ~ 1650

0,42 ~ 0,53

Pure lead

1515 ~ 1680

0.42 ~ 0.45

Silver

Polished Silver

100

0.05

Material

Temperature

(°C)

Emissivity

(approx.)

Nickel

Nickel-chrome

(heat-resistant)

50 ~ 1000

0.65 ~ 0.79

Nickel-chrome alloy

50 ~ 1040

0.64 ~ 0.76

Nickel-chrome alloy

(heat-resistant)

50 ~ 500

0.95 ~ 0.98

Nickel-silver alloy

100

0.14

Lead

Pure lead

(non-oxidised)

125 ~ 225

0.06 ~ 0.08

Stainless steel

18 - 8

25

0.16

304 (8Cr, 18Ni)

215 ~ 490

0.44 ~ 0.36

310 (25Cr, 20Ni)

215 ~ 520

0.90 ~ 0.97

Tin

Commercial tin plate

100

0.07

Strong oxidization

0 ~ 200

0.60

Zinc

Oxidizing at 400°C

400

0.01

Galvanised shining

iron plate

28

0.23

Ash zinc oxide

25

0.28

Magnesium

Magnesia

275 ~ 825

0.55 ~ 0.20

Hg

0 ~ 100

0.09 ~ 0.12

Nickel

Electroplate polishing

25

0.05

Electroplate

20

0.01

Nickel wire

185 ~ 1010

0.09 ~ 0.19

Nickel alloy (oxide)

198 ~ 600

0.37 ~ 0.48

11. eMIssIvIty taBLe