Maintenance

SeaKing & SeaPrince Imaging Sonars

0374-SOM-00001, Issue: 08

37

© Tritech International Ltd.

6.4.1. Disassembly of the Super SeaPrince unit

Warning

In the unlikely event that the subsea housing has suffered water ingress at depth

there may be internal pressurization. This could forcibly eject the end-cap when

the lock ring is removed.

If wishing to dismantle the unit, for any reason, due care and attention should

be taken to prevent damage or injury.

Important

The steps outlined here will expose sensitive electronic equipment and so

appropriate steps should be taken to prevent any static discharge occurring

which may harm the equipment.

Caution

Servicing of the SeaKing unit should only be carried out by competent personnel

in a dry, clean environment with full ESD precautions.

Service tools required

• Clean absorbent wipes

• Silicon grease MS-111 lubricant (or equivalent)

• A M3 Allen Key or Hex driver

Procedure

1. Rinse the unit and connector in fresh water and dry with absorbent wipes

2. Using the M3 Allen key, loosen each of the retaining screws of the Pressurised blanking

cap (if present)

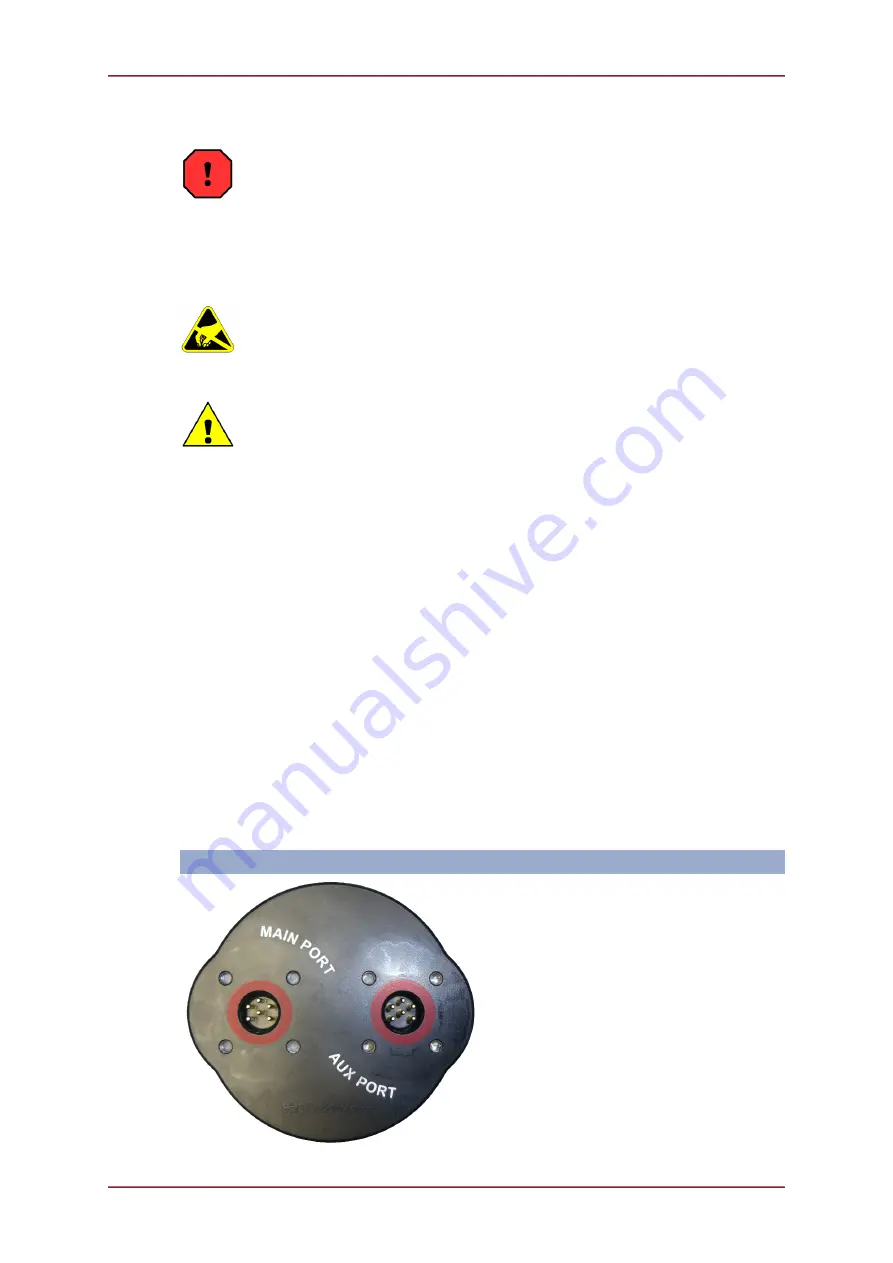

3. Using the M3 Allen key, loosen each of the retaining screws of the MAIN and AUX (if

present) waterblocks. Each screw should be loosened by a quarter turn in order to prevent

damage to the screw threads.

Once fully disassembled, inspect the various o-ring seals and sealing surfaces for signs of

damage and corrosion. Pitting and corrosion within an o-ring sealing area can cause a unit

to lose integrity and lead to water ingress and significant damage.

Waterblock O-Rings