Trinity Lx

│

Plumbing and Wiring Instructions Water Heater Applications

12

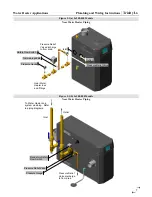

Multiple Water Heater Applications

The Lx controller has the internal capacity to stage or Lead-Lag up to 8 water heaters configured in a cascade.

This Lead-Lag capability allows a designated “Master” water heater to communicate with and effectively control

each water heater in a multiple water heater system. This function is accomplished by “Daisy Chaining” a 3-

wire cable between each of the water heaters and enabling the Master parameter in the water heater of your

choice. The water heater with the Master parameter enabled becomes the single point of contact for settings and

control wiring. Use the instructions detailed in this section to set-up and install the cascade water heater system;

reference

Appendix A – Controller and Touchscreen Display Instructions

for details on more advanced settings

and for assistance with navigating the touchscreen display.

Lead Lag Instructions

Plumbing

– install as many as 8 Lx water heaters in a parallel plumbing configuration as illustrated in Figure 2-3.

Size common piping as per Table 2-5.

Water Heater Pump

– each water heater must have its own circulator (see Figure 2-3) which is controlled by its

PUMP B

output; see

Field Wiring

Figures and Tables 3-1(a) and 3-1(b). The water heater pump must be sized

according to Table 2-4.

Communication Wiring

– using 3-wire cable, daisy-chain terminals

LL DATA +

, LL

DATA –

and

SENSOR

COM

of each water heater in parallel; see

Field Wiring

Tables 3-2(a) and 3-2(b) and Figure 3-2.

System Sensor

– a system sensor is

NOT

used in a water heater application, at the Master boiler set the

applicable sensor input to

Unconfigured

as follows:

Configure

– Sensor Configuration – S10 (J10-7) sensor [S5 (J8-11) sensor

for Lx500-800 models

]

Modbus Address –

assign a unique

MB2 Modbus Address

to each water heater in the cascade. Access the

MB2

Modbus Address

setting via the

System Identification & Access

menu as follows:

Configure

– System Identification & Access – MB2 Modbus Address

Master Enable

– choose

one

(and only one) water heater in the cascade to be the Master, this water heater will

receive all control wiring and will be used for setting control parameters (see steps below). On this one water

heater, set

Master enable

equal to

Enabled

via the

Lead Lag Master Configuration

menu, accessed as follows:

Configure

– Lead Lag Master Configuration – Master enable

Tank Thermostat

– connect to

SENSOR COM

and

DHW

of the Master water heater; see

Field Wiring

Tables 3-

2(a) and 3-2(b) and Figure 3-2. Switch must be an isolated end switch (dry contact).

DHW Setpoint

– at the Master water heater only, set the

DHW setpoint

via the

Lead Lag Master Configuration

menu, accessed as follows:

Configure

– Lead Lag Master Configuration – DHW setpoint

DHW switch (Lead Lag)

– at the Master water heater only, set

DHW switch

equal to

DHW (S6) sensor shorted

via the

Lead Lag Master Configuration

menu, accessed as follows:

Configure

– Lead Lag Master Configuration – Advanced Settings – Domestic Hot Water – DHW switch

DHW enable (Local)

– at the Master water heater only, set

DHW enable

equal to

Disabled

via the

Domestic Hot

Water Configuration

menu, accessed as follows:

Configure

– Domestic Hot Water Configuration – DHW enable

Tank Sensor

– when operating in a cascade system, the water heater controls do not

support the use of a tank sensor; a tank thermostat (switch) must be used.