TMCM-078 Manual (V1.03 / September 10th, 2008)

20

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

5.3.2

Step

Description:

The Step signal controls the velocity and acceleration of the motor. The velocity depends

on the frequency, the acceleration on the change of the frequency. One step impulse represents one

microstep.

Calculation of rotations per second:

]

s

/

rotations

[

resolution

Microstep

Fullsteps

frequency

input

Step

]

s

/

rotations

[

v

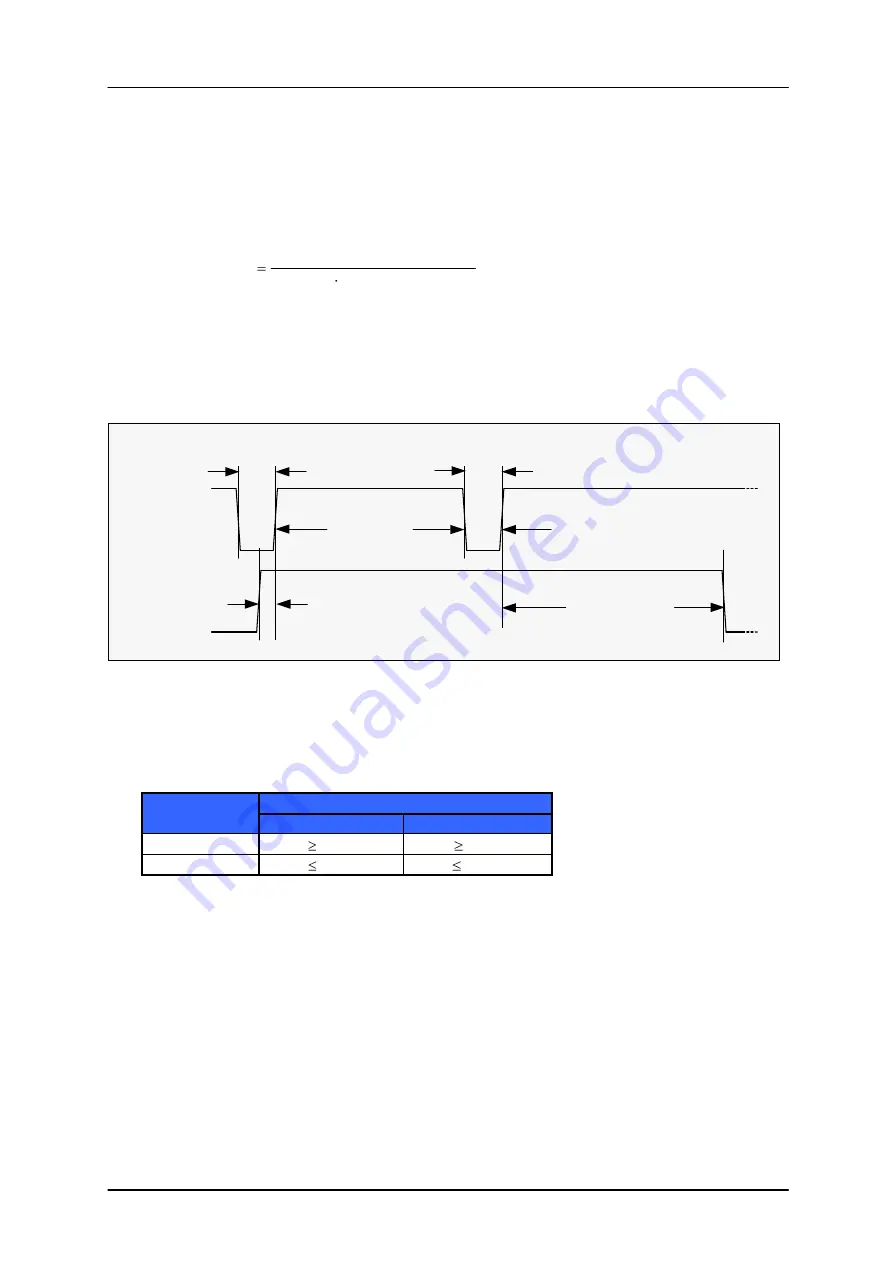

Maximum frequency at screw connector (decoupled by opto couplers):

The maximum Step input

frequency is 350 kHz, aligned to the Direction signal. It is limited by the switching capabilities of the

optocouplers. The minimum logic ”0” time is 0.7 µs and the minimum logic “1” time is 2.0 µs. A step

is triggered by the positive going edge of the signal (switching off of opto coupler).

Maximum frequency at a duty cycle of 1 (“0” time is 2.0 µs and “1” time is 2.0 µs) is 250 kHz.

step pulse

direction

0.7µs min

2.0µs min

0.7µs min

t

DIRHOLD

t

DIRSETUP

Figure 5.3: Step and Direction Signal (schematically, optocoupler input at screw connector)

Maximum frequency at JST connector:

Even higher than at screw connector. Limited by

microcontroller but not yet evaluated (approximately 300 kHz without microstep loss).

Function Table:

Step signal

Differential signal

Screw connector

JST connector

high

3.5 V

0.4 V

low

2.0 V

-0.4 V

5.4

RS485 interface

The RS485 interface can control all functions of the TMCM-078. It is possible to change parameters,

with this interface which are also valid in the other modes like max. velocity or acceleration. Most of

the parameters that can be change by the RS485 commands (except those that are set by the DIP

switches) can also be stored in the FlashROM of the module.

The factory default address setting is “A” and the default baud rate is 9600 baud. Use an appropriate

RS485 interface (like Trinamic USB-2-485) to enter RS485 commands using a terminal program (e.g.

Hyperterminal that is shipped with Windows).

Many commands are the same as those used on the TMCM-013 and IDX modules, but some

commands are different. Also the parameter ranges of many commands are different from those on

the TMCM-013 and IDX modules.