PD-013-42 / TMCM-110-42 Manual (V1.24/2011-NOV-25)

23

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

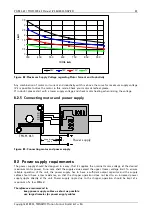

Figure 8.2: Maximum Supply Voltage regarding Motor Current and Inductivity

Any combination of motor coil current and inductivity witch is above the curve for maximum supply voltage

(V

S

) is possible to drive the motor in this mode. Check your motor datasheet please.

If in doubt, please start with a lower supply voltage and check motor heating when raising the voltage.

8.2.5

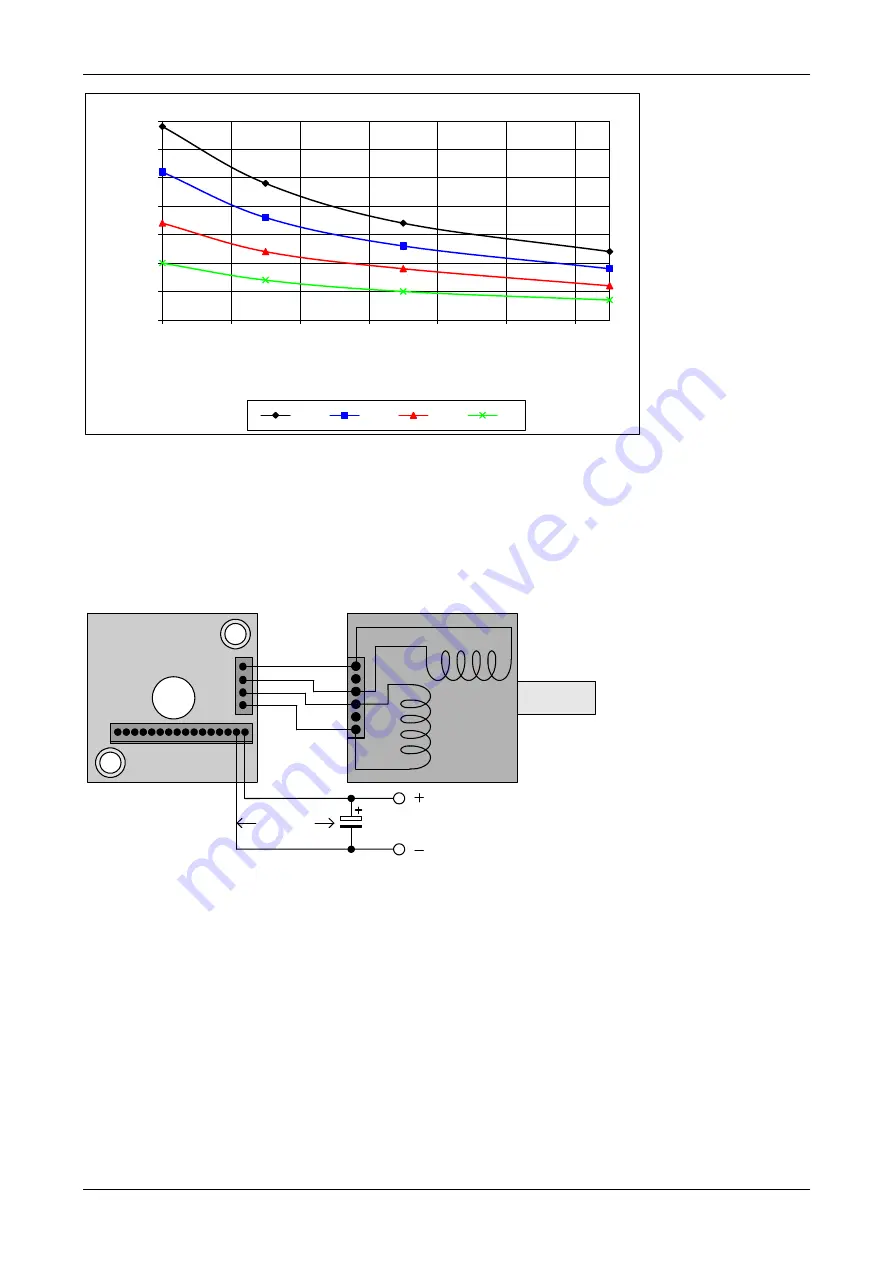

Connecting motor and power supply

TMCM- 013

OB2

OB1

OA2

OA1

Power supply

C

keep distance

short

Figure 8.3: Connecting motor and power supply

8.3

Power supply requirements

The power supply should be designed in a way, that it supplies the nominal motor voltage at the desired

maximum motor power. In no case shall the supply value exceed the upper / lower voltage limit. To ensure

reliable operation of the unit, the power supply has to have a sufficient output capacitor and the supply

cables should have a low resistance, so that the chopper operation does not lead to an increased power

supply ripple directly at the unit. Power supply ripple due to the chopper operation should be kept at a

maximum of a few 100mV.

Therefore we recommend to

-

keep power supply cables as short as possible

-

use large diameter for power supply cables

0

0,5

1

1,5

2

2,5

3

3,5

350

450

550

650

750

850

950

L

/mH

ICOIL /mA

24V

18V

12V

7V