Prestige SOLO 110 and EXCELLENCE

Natural to LP Conversion

Instructions:

1. Turn power to the unit “OFF” and allow unit to

cool.

2. Shut off gas supply to the inlet of the unit at the

main manual shutoff valve to the unit.

3. Remove the front panel of the Prestige by

removing the thumb screw on the upper edge of

the unit. Lift the panel up and pull forward to

remove the front panel from the unit.

4a. Remove the retaining screw from the control

panel. Open the display panel cover and swing

the control panel out (MCBA).

4b. Depress the retaining clips and tilt the control

panel down (TriMax).

5. Remove the air inlet elbow from the venturi

using a twisting motion.

6. Disconnect the gas supply piping inside the

Prestige enclosure at the brass union located

just below the gas valve.

7. Unscrew the Phillips screw securing the rectifi-

er cable / plug to the gas valve. Disconnect the

rectifier plug from the gas valve (MCBA).

8. Remove molex plug from gas valve (TriMax).

9. Disconnect the ignition cable from the igniter

(MCBA), and remove the ground wire at the

igniter.

To ease the removal of the burner assembly,

remove the top jacket access panel.

10. Disconnect the wiring harness connectors from

the blower and remove the blower retaining

screws. Remove the blower with venturi and

gas valve from the unit.

11. Remove the 10 mm nuts and remove the burn-

er mounting plate assembly from the heat

exchanger body.

12. Remove the combustion chamber insulation

from the heat exchanger. See WARNING on

page 7.

13. Remove the Phillips head screws attaching the

burner head to the burner mounting plate.

Remove and discard the old burner head and

burner head gasket.

If the gasket “sticks” to the burner mounting

plate use a flat blade putty knife to remove

any gasket material. Ensure not to scratch or

score the mating surface.

For the reassembly process do not use adhe-

sives on ANY gasket surface.

14. With the new gasket in place attach the new burn-

er head to the burner mounting plate using the

screws supplied in the kit, as shown in Fig. 2.

NOTICE

NOTICE

NOTICE

2

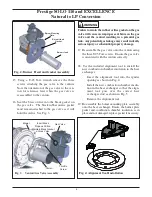

Gas Piping

Union Connection

Combustion

Chamber Insulation

10 mm

Mounting Nuts

Ignition Cable

Fig. 1: Burner Assembly