16

S8XB-SVX001-1A-EN

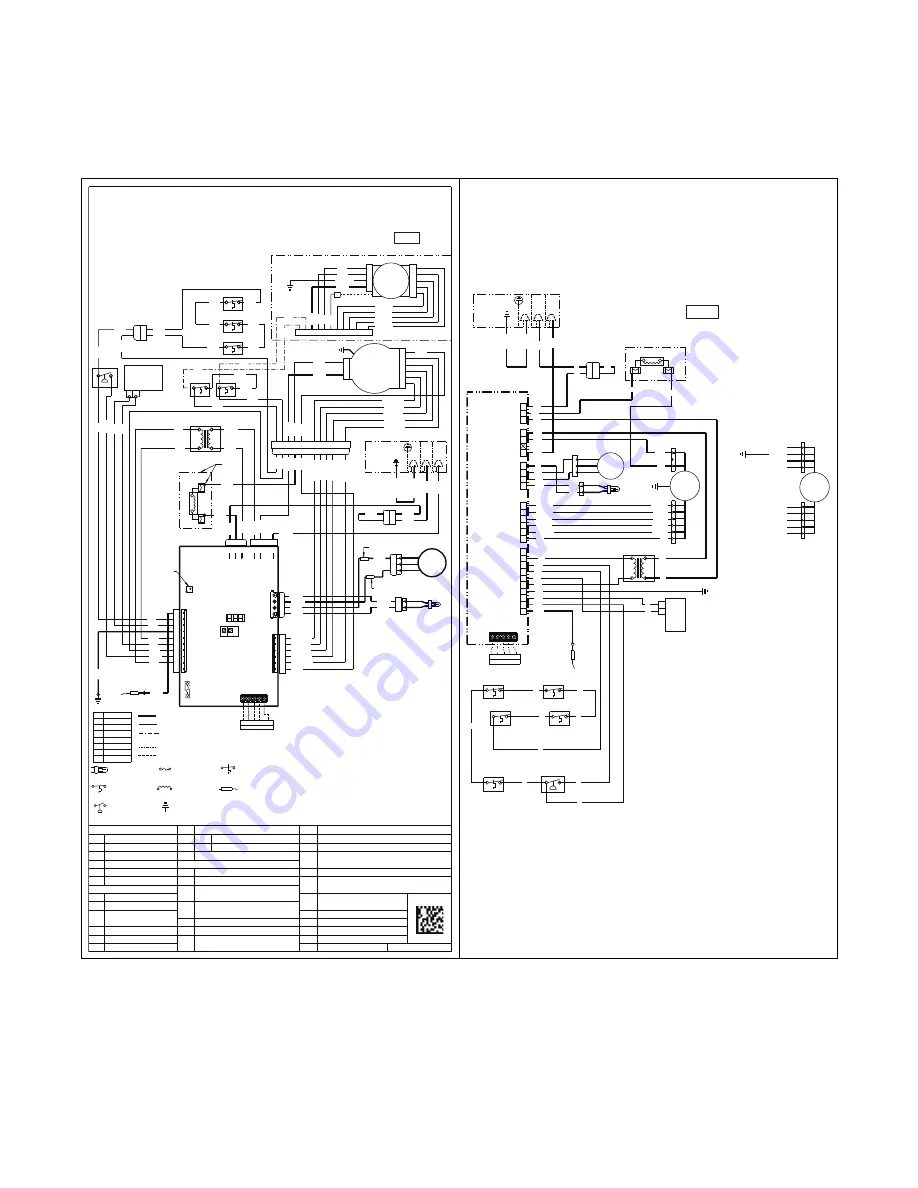

Wiring Diagrams

BK BLACK

WH WHITE

YL YELLOW

OR ORANGE

GR GREEN

BR BROWN

RD RED

BL BLUE

YL/44

YL/43

WH/40

WH/40

BK/WH/38

YL/46

YL/5

2

WH/17

WH/17

WH/21

WH/21

BK/22

BK/22

WH/20

BK/18

BL/2

BL/2

BL/5

BL/5

RD/6

RD/6

RD/9

RD/9

8/

R

G

WH/12

YL/50

YL/50

YL/49

YL/49

G

R

/YL/31

13/

L

Y/

R

G

YL/51

YL/51

YL/48

YL/48

BK

/29

BK/29

OR/11

O

R

/11

YL/47

74/

L

Y

BOX HARN

TO BURNER

BURNER BOX

GND

NOTES:

1. IF ANY OF THE ORIGINAL WIRING SUPPLIED WITH THIS FURNACE MUST BE REPLACED, IT MUST BE WITH WIRE

HAVING A TEMPERATURE RATING OF AT LEAST 105°C. WIRES 12, 18, 20, 48, 49, 50, 51, 92 & 93 MUST BE RATED TO 250°C.

2. FOR PROPER AIRFLOW IN COOLING/HEAT PUMP MODE, "Y1" ON THE THERMOSTAT MUST BE CONNECTED TO "Y1"

OF THE IFC. SEE INSTALLER'S GUIDE FOR FIELD WIRING.

3. THE INDOOR BLOWER MOTOR AIRFLOW TABLES ARE LOCATED IN THE SERVICE FACTS. TO CHANGE AIRFLOW USE

THE MENU/OPTIONS BUTTONS.

4. LINE CHOKE AND WIRE BK/28 ONLY USED ON MODELS WITH 1 HP MOTORS.

5. FLAME SENSE TEST PADS: 1 VDC = 1 MICROAMP. FLAME CURRENT CAN VARY DEPENDING ON THE VOM THAT IS USED

AND THE VOLTAGE SUPPLIED TO THE FURNACE.

THE ACCEPTABLE RANGE IS 0.75-3 MICROAMPS.

6. IF APPLICABLE CONNECTION FOR FACTORY

SEE NOTE 2

ELECTRICAL RATING

INPUT: 24VAC, 60 HZ.

TNS SEC. CURRENT: 450MA.

+ MV LOAD

MV OUTPUT: 1.5A @ 24 VAC

IND OUTPUT: 2.2 FLA, 3.5 LRA

@120 VAC

IGN OUTPUT: 2.0 A @ 120 VAC

CIRC. BLOWER OUTPUT:

14.5 FLA, 25 LRA @ 120 VAC

HUMIDIFIER & AIR CLEANER

(DRY CONTACTS)

MAX. LOAD: 1.0A @ 120VAC

24 VAC OR 120 VAC MAY BE

USED

FUSE: 5A

INTEGRATED FURNACE CONTROL

LINE

24 V

LINE

24 V

FIELD

WIRING

FACTORY

WIRING

RAF REVERSE

AIR FLOW

PS PRESSURE

SWITCH

FRS FLAME ROLLOUT

SWITCH

FP FLAME PROBE

IGN HOT SURFACE

IGNITER

** INTERNAL THERMAL PROTECTION

FUSE

GROUND

SEE NOTE 5

PANEL LOOP

H LINE

N NEUTRAL

GND GROUND

HLO HIGH LIMIT

OUTPUT

HLI HIGH LIMIT

INPUT

PS PRESSURE SWITCH

INPUT

IND INDUCER

IFC INTEGRATED

FURNACE

CONTROL

RAF REVERSE

AIR FLOW

TH 24VAC (HOT)

TR 24VAC (COMMON)

MVC MAIN VALVE

COMMON

MV MAIN VALVE

TNS TRANSFORMER

ILI INDUCER LIMIT

INPUT

IGN IGNITER

FP FLAME PROBE

YL/45

YL/45

WH/15

WH/15

W

H/16

WH

/16

YL/3

YL/3

BK/39

BK/39

YL/WH/36

BL/WH/37

BK

/14

BK/14

BK/13

BK/13

BK/WH/26

BK/WH/26

BL/WH/25

BL/WH/25

YL/WH/24

YL/WH/24

RD

/W

H/23

RD/WH/23

RD/WH/35

BK/28

B

K/28

BL/57

BL/57

OR/WH/56

O

R

/WH/56

OR/WH/55

BL/42

BL/42

BK/30

BK/27

SEE

NOTE 4

LC LINE CHOKE

YL/46

YL/52

TIMINGS

PREPURGE: 0 SEC.

INTERPURGE: 60 SEC.

POST PURGE: 5 SEC.

IGN WARMUP: 20 SEC.

IAP: 3; TFI: 5 SEC.

RETRIES: 2 RECYCLES: 10

HEAT ON DELAY: UP TO 30 SEC.

COOL ON DELAY: 0 SEC.

AUTO RESTART: 60 MIN.

AUTO RESTART PURGE: 60 SEC.

1 Stage Inducer with CTM Blower Motor

D346340P01 REV H

HOd

Heat Off Delay (sec)

IdL

Idle

COF

Blower Tap for Continuous Fan

Ht

Heating

COP C1

.

Blower Tap for Compressor Mode

E04

tP

Blower Tap Number

COF

Continuous Fan

E05

CP1

Cooling/Heat Pump Mode

dft

Defrost Mode

HtP H1

.

Blower Tap for Heating Mode

rUn

Orn

Orientation

Err

Active Alarm Menu

E01

L6F

Last 6 Faults (To Clear,

Hold Option Button 5 sec)

E08

Flame current is low, but still

strong enough to allow operation

Cr

Code Release Number

E11

(1) Gas valve not energized

(2) Gas valve relay stuck closed

COd

Cooling Off Delay (sec)

E12

Open fuse

Open Pressure Switch

(1) Igniter relay fails

(2) Igniter open

Status Codes

Menu Options

Open Thermal Limit, Rollout Switch,

or Reverse Airflow Switch

Shorted Pressure Switch

Flame detected, should not be present

Voltage reversed polarity

Bad Grounding

Error Codes

Run Test Mode

Recycles exceeded (loss of

established flame or PS open x10)

Gas Valve not energized when it

should be exceeded after 10 times

Loss of IRQ or internal failures

Retry exceeded (Failed to est flame)

Gas valve is energized whenit should be off

WH/83

WH/83

BK/WH/84

BK/85

BK/85

YL/WH/86

BL/WH/87

RD/WH/88

OR/WH/89

BL/90

BL/90

GR/BK/91

ALTERNATE WIRING DIAGRAM - BLOWER MOTOR

BK/92

WH/93

BUTT SPLICE-WITH HEAT SHRINK

BUTT SPLICE-WITH HEAT SHRINK

85/

L

B

SEE NOTE 6

59/

L

Y

YL/95

YL/96

YL/96

ALTERNATE

X

X

24v

120v

TNS

VENT

MOTOR

(INDUCER)

**

GAS

VALVE

MV C

RAF-1

IGN

PS

X

THERMAL_LIMIT

FLAME_ROLLOUT2

FLAME_ROLLOUT1

FLAME_PROBE

FP

HLI

MV

GND

TH

MVC

HLO

PS

TR

ILI (NOT USED)

IGN-N

IND-N

IND-H

IGN-H

IFC

LINE

NEUTRAL

W R G B/C Y/Y1

THERMOSTAT

FP

MENU OPTION

TAP1

TAP2

TAP3

TAP4

TAP5

GND

LINE-N

CIRC-N

(bloc

k

e

d)

TNS-N

TNS-H

CIRC-H

LINE-H

3

2

1

4

3

1

2

1

2

2

1

1

2

JUNCTION BOX

120v 60 Hz. 1 PH

POWER SUPPLY PER LOCAL CODE

H

N

GND

X

RAF-2

10

9

8

7

6

5

4

3

2

1

1

2

3

4

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

6

5

4

3

2

1

1

2

3

1

2

3

4

1

2

2

1

1

2

3

LINE CHOKE

REGAL -ENSITE

BLOWER

MOTOR

N

G

L

COM

®

1

2

3

4

5

6

1

2

3

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

1

2

3

4

BLOWER

MOTOR

C

L

G

N

S1

1

2

S2

1

2

E2

.

1

E2

.

2

E2

.

3

E3

.

1

E3

.

2

E6

.

1

E6

.

2

E6

.

3

E7

.

1

BLOWER

HOUSING

GND

BLOWER

HOUSING

GND

SEE NOTE 1

SEE NOTE 1

PROGRAMMING ONLY.

S8B1

BL

BL

RD

RD

YL

YL

YL

BK

WH

GR/YL

GR/YL

YL

GR

YL

YL

YL

BK

BK

WH

WH

BK

BK

BK

BK

BL

RD

BK

BK

WH

WH

YL

YL

OR

OR

BURNER

BOX GND

BK

PANEL LOOP

YL

WH

WH

WH

RD/WH

RD/WH

BL/WH

BL/WH

BK/WH

BK/WH

BK

BK

BL

BL

OR/WH

OR/WH

YL/WH

YL/WH

BK

BK

WH

WH

DEFAULT BLOWER MOTOR TAP SELECTIONS

COF (CONSTANT FAN): TAP 1

COP (COOLING / HP): TAP 7

HT ( GAS HEAT): TAP 5

®

VENT

MOTOR

(INDUCER)

**

1

2

3

IGN

ILI

TR

PS

HLO

MVC

TH

GND

MV

HLI

FP

W R

G B/C Y/Y1

THERMOSTAT

LINE-H

CIRC-H

TNS-H

TNS-N

CIRC-N

LINE-N

IGN-H

IND-H

IND-N

IGN-N

1

2

3

4

5

6

7

8

9

10

1

2

3

4

4

3

1

3

2

1

IFC

TAP1

TAP2

TAP3

TAP4

TAP5

GND

1

2

3

4

5

6

JUNCTION BOX

120v 60 Hz. 1 PH

POWER SUPPLY PER LOCAL CODE

H

N

GND

24v

120v

TNS

GAS

VALVE

MV

C

FLAME_ROLLOUT1

FLAME_ROLLOUT2

RAF-1

THERMAL_LIMIT

REGAL

ENSITE

--------

BLOWER

MOTOR

N

4

3

2

1

G

L

5

COM

PS

FLAME PROBE

1

2

RAF-2

2

1

LINE CHOKE

ALTERNATE

-------

BLOWER

MOTOR

G

N

4

3

2

1

L

C

5

TO: IFC CIRC-N-3 WH

TO: LINE CHOKE BK

TO: IFC GND-6 BL

TO: IFC TAP1-1 RD/WH

TO: IFC TAP2-2 YL/WH

TO: IFC TAP3-3 BL/WH

TO: IFC TAP4-4 BK/WH

TO: IFC TAP5-5 OR/WH

GR/BK

BLOWER

HOUSING

GND

BLOWER

HOUSING

GND

S8B1