Operating Procedures

ARTC-SVX002A-EN

41

water solutions become slushy during freezing. As the

temperature falls, the slush becomes more and more

viscous and finally fails to flow.

The precise concentration of glycol for a particular chiller

is affected by several key factors such as ambient

temperature extremes, entering and leaving water

temperatures, and chiller size. A chiller’s optimum glycol

concentration is modified by these considerations as

reflected in above Table, Glycol Performance Impact

Factors. These capacity correction factors are the “best

informed estimates” for chillers with copper evaporators.

The percentages may vary depending on the materials

and alloys of the heat exchangers, total surface area, the

amount of present or future fouling, and the brand of

glycol used.

The calculations in this table are most accurate for

Dowfrost (propylene glycol) and Dowtherm (ethylene

glycol) branded products. Consult your local supplier or

engineering contractor for more precise

recommendations.

Storage Provisions

The chiller controls are designed for storage in ambient

temperatures from -20 °F (-29 °C) to 145 °F (63 °C) with

relative humidity from 0% to 100%. The glycol should be

removed from the chiller if the unit is to be stored for

extended periods. Although fluids can be drained via the

plug in the bottom of the evaporator, the inhibitors in an

approved glycol solution will best protect the surfaces of

the evaporator against oxidation if the glycol remains

inside the chiller during storage.

Table 8.

Freeze protection chart

Water/Glycol

Temperature

Freeze Protection Burst Protection

20 °F (-7 °C)

18% glycol mixture

12% glycol mixture

10 °F (-12 °C)

29% glycol mixture

20% glycol mixture

0 °F (-17.8 °C)

36% glycol mixture

24% glycol mixture

-10 °F (-23 °C)

42% glycol mixture

28% glycol mixture

-20 °F (-29 °C)

46% glycol mixture

30% glycol mixture

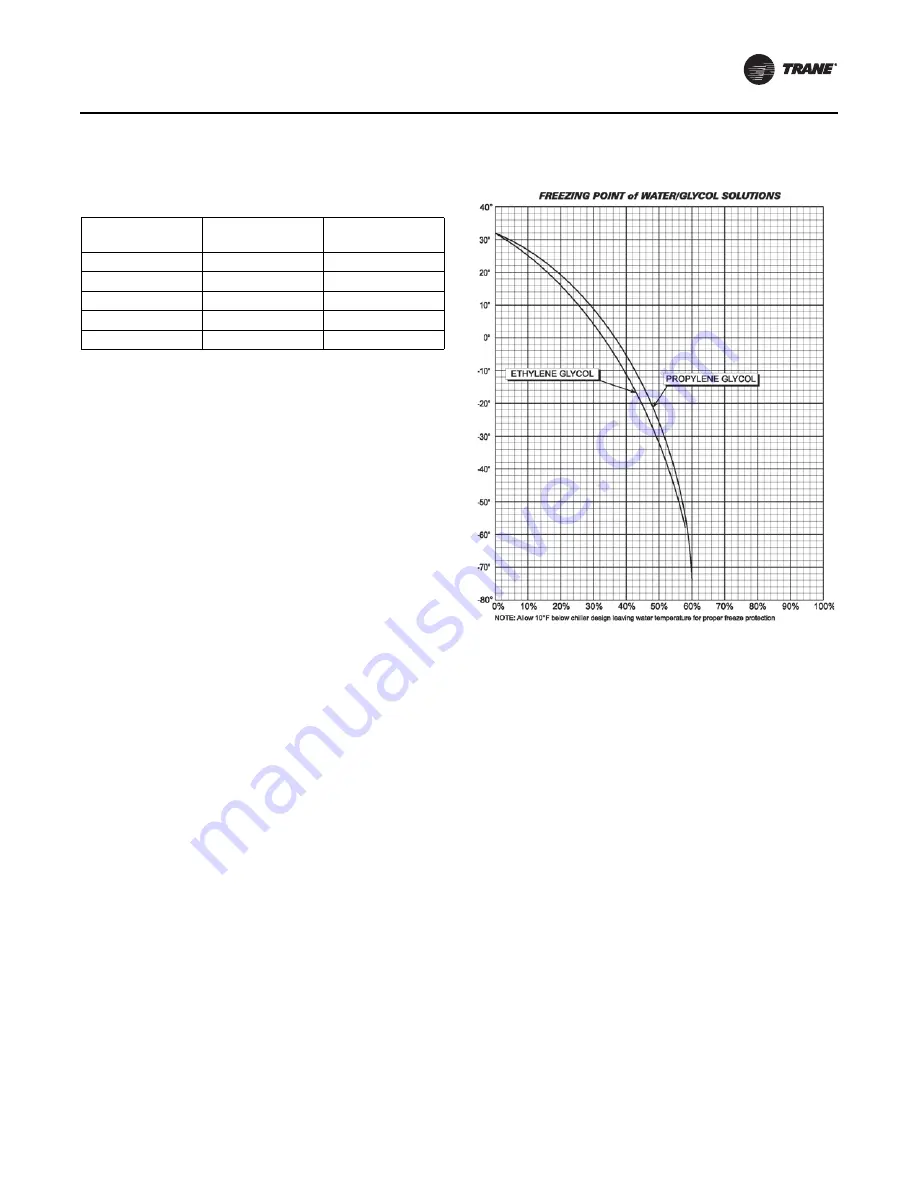

Figure 19.

Water/Glycol concentration freezing points

(in degrees fahrenheit)