52

Operating principle

In the electrode boiler humidifier, the current flowing between the electrodes in the water in the cylinder generates the

heat necessary to boil the water.

By controlling the water level and the concentration of salt measured in the steam cylinder (U1) using the feed water

solenoid valve (U8) and the boiler cylinder electric drainage valve (U9), the electric current is regulated by means of an

amperometric transformer (U11).

When steam is needed, the humidifier contact is closed (see the electrical diagram) which provides power to the

immersed electrodes. When the current falls below the value required as a result of the fall in the water level, the feed

water solenoid valve is opened (U8).

the boiler cylinder electric drainage valve (U9) is opened at intervals depending on the characteristics of the feed water

supply in order to maintain the optimum concentration of dissolved salts in the water in the cylinder (U1).

Feed water

Values for the feed water for medium-high level of conductibility of a humidifier with immersed electrodes.

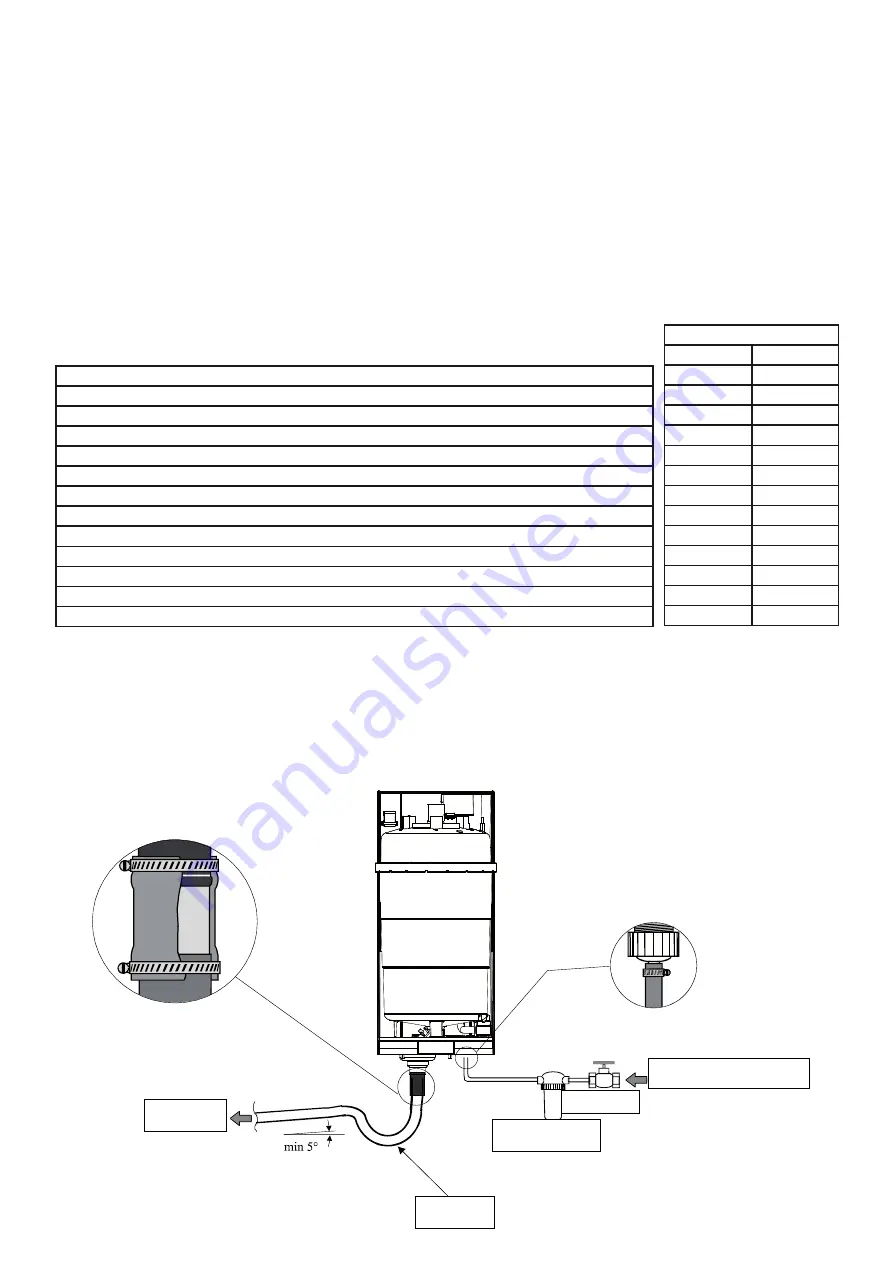

Connections

The installation of the humidifier requires connection to the feed tubes of the water drain.

(1) Values dependent on the specific conductibility; in general: TDS @ 0,93 * s20; R180 @ 0,65 * s20

(2) not lower than 200% of the Chloride content in mg/l di Cl-

(3) not lower than 300% of the Chloride content in mg/l di Cl-

Hydrogen ion activity

pH

-

Specific conductibility at 20 °C

, 20 °C

-

µS/cm

total dissolved solids

tDS

-

mg/l

Residual fixed at 180 °C

r180

-

mg/l

total hardness

tH

-

mg/l CaCo3

temporary hardness

-

mg/l CaCo3

iron + Manganese

-

mg/l Fe + Mn

Chlorides

-

ppm Cl

Silica

-

mg/l Sio2

residual chloride

-

mg/l Cl-

Calcium sulphate

-

mg/l CaSo4

Metallic impurities

-

mg/l

Solvents, dilutents, soaps, lubricants

-

mg/l

Feed tubes

Siphon

Filter

Drain

valve

LiMitS

Min.

Max.

7

8.5

300

1250

(

1

)

(

1

)

(

1

)

(

1

)

100(

2

)

400

60(

3

)

300

0

0.2

0

30

0

20

0

0.2

0

100

0

0

0

0