10

TRAK Machine Tools

Southwestern Industries, Inc.

Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual

3.3

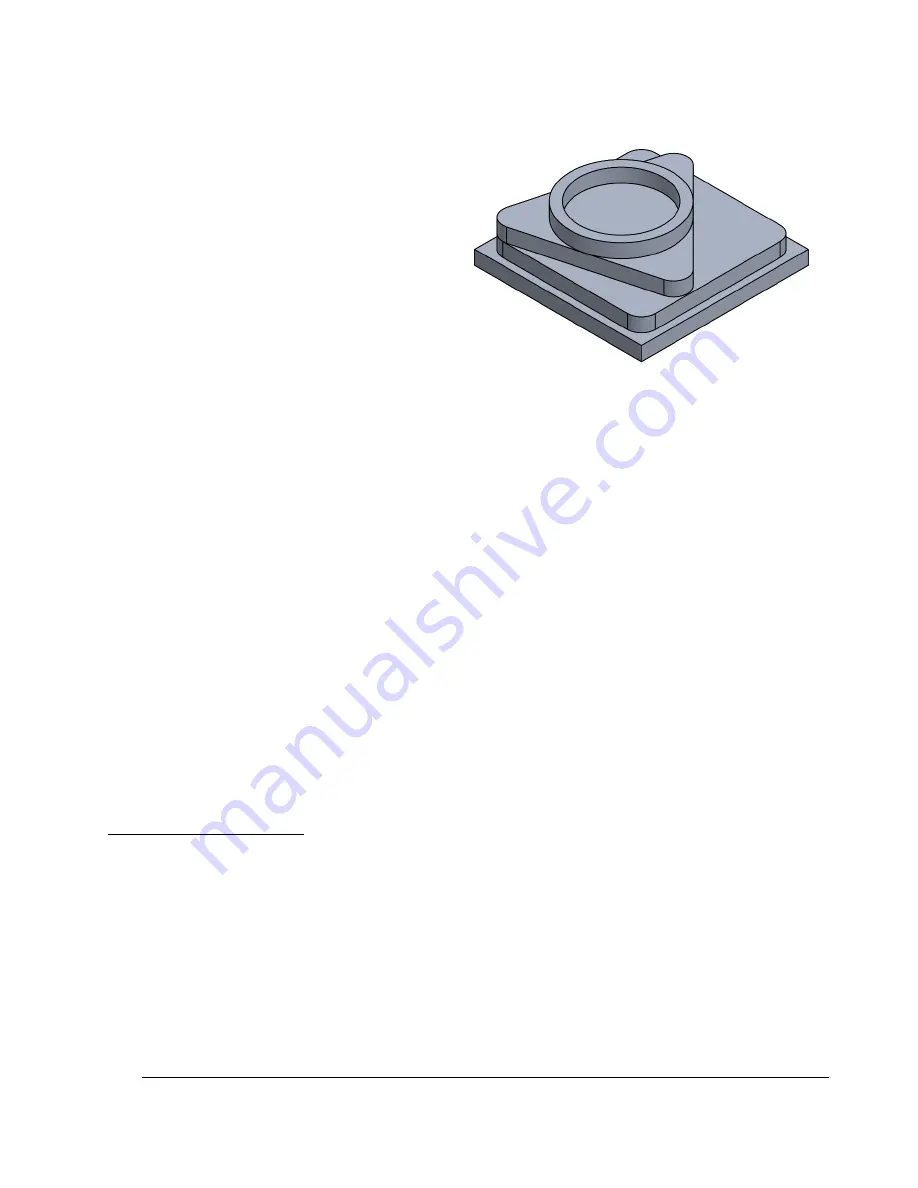

Benchmark Part: Euclid Block

In the accessory box, with your new printer, you will

find a 3D printed part, called a Euclid Block. We

printed it directly from your printer, using MG94

ABS, and the exact same G-Code file that we saved

onto your printer's Internal Drive as "LEFT TRAK".

Purpose

The Euclid Block helps establish a printing baseline

for your printer, which we can reference if/when you

are experiencing any printing issues.

Because 3D printed parts can differ from one

another based on many variables; material type, material care, slicer settings, printer, printer

maintenance, and so on, diagnosing a problem can be difficult to isolate.

Therefore, by using the G-Code we provided, we are controlling the slicer setting variables. By using the

material we provided (make sure its dried!), we are controlling the material variables.

Now we can begin to isolate the problem in a much more controlled manner!

Printing the Euclid Block

When you print it, make sure you follow the requirements below:

•

Use MG94 ABS, natural color, and make sure it is DRY.

•

Use the exact same G-Code we saved on your internal drive. If you need another copy, call TRAK

Customer Service.

•

Make sure you watch the first layer print before walking away from your printer.

Troubleshooting

Once the Euclid Block is printed, you can look at it, and see what it is telling you. Is there warping? Are

the layers delaminating? Are there bubbles on the top layer? Are the top and bottoms layers bigger than

the middle layers? Is the overall print quality bad?

Below is an example of how we can help you start troubleshooting, using the Euclid Block:

Example #1

The first layer of your block did not adhere to the build plate. One potential cause could be the WolfBite.

WolfBite Issues and Solutions

1.

Not enough was applied initially. Remove & apply more before restarting the print.

2.

Too much was applied initially. Remove & apply again before restarting the print.

3.

It did not dry sufficiently, allow 5 minutes the next time you apply it

4.

It needs to be replaced, it is either too old or the wrong kind

If the WolfBite suggestions above did not fix the problem, the next steps would be to check if the

chamber heater needs to be on. If

that didn’t work, then you would move onto the next potential cause.

Regardless, if your printer has an issue, call TRAK Customer Service to have a Technical Support, or

Applications Specialist walk you through the process

–

you’re not alone! We’re here t

o help.