142

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

Caution!

Binding in the quill travel will impair system performance and may

damage the ball screw assembly.

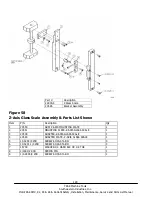

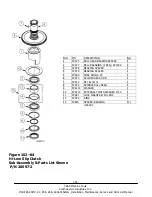

19

98029A036

WASHER-FINISHED FLAT-CASE HARDENED STL

EA

1

20

3/4-16 51Z

NUT-HEX JAM-STL-ZINC-GRADE 2

EA

1

21

16364-3

SCREW 3/8-24 BRKT BALLNUT MOUNTING

EA

1

22

16739

JACKSCREW NUT

EA

1

23

14932

WASHER-LOWER BOLT

EA

2

24

15759

WASHER-1/4 HARD BLK OX 1/8 THK

EA

2

25

16355-3

SCREW M10.-1.0. BRKT. BALLNUT MOUNTING

EA

1

26

16365

SPACER CENTERING HOLE

EA

1

27

16212-175

COUPLING SOCKET HEAD

EA

2

28

1/4-20 56Z

NUT-NYLON LOCK-STL-ZINC

EA

2

29

16357-2

BRACKET BALLNUT FORK EXT SUPERMAX 16VS

EA

1

30

1/2-13X1 1/2 25B SCREW-SHCS-STL-BO

EA

2

31

1/4-20X1 3/4 25B SCREW-SHCS-STL-BO

EA

2

32

1/4-20X1 40B

SCREW-SOC SET-STL-BO-CUP

EA

4

33

1/4-20X3/4 25B

SCREW-SHCS-STL-BO

EA

2

34

1/4-20X3/8 40B

SCREW-SOC SET-STL-BO-CUP

EA

4

35

3/8-16 50B

NUT-HEX-STL-BO

EA

1

36

3/8 70P

WASHER-FLAT USS-STL-BO

EA

1

37

3/8 73B

WASHER-SPLIT LOCK-STL-BO

EA

2

38

16210-1

POSITIONER LOCATOR

EA

2

39

M6-1.0X25 25B

SCREW-SHCS-STL-BO

EA

2

40

M10 73B

WASHER-SPLIT LOCK-STL-BO

EA

1

41

16740

COUPLING SOCKET HEAD

EA

1

42

¼-20 x 1 1/4 25B SCREW-SHCS-STL-BO

EA

4

43

3/8-24 x 2 ¼ 25B SCREW-SHCS-STL-BO

EA

1

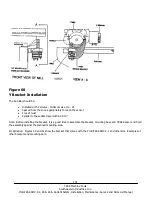

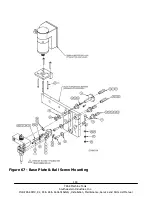

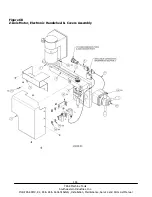

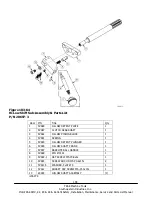

i25000-XX

8.2 Installation of the Ball Screw

1. Install the ball screw assembly as shown in Figure 67. Run the quill up and down over its full travel at each step to

ensure that there is no binding. Adjust as necessary. You can mount a dial indicator on the top of the table, locating off

the ballscrew. Move the knee up and down and tram in the ballscrew from front to back with the leveling nuts.

Note: Loosely install the ball screw at first, and then attach the fork with the quill near the top of its travel.

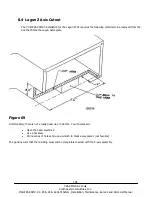

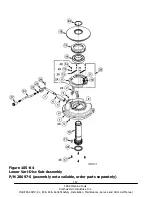

8.3 Installation of the Motor and Remaining Components

See figure 67 & 68

1. Install the motor mounting bracket to the top of the base plate.

2.

Install the motor to this bracket. Install the belt between the pulleys and tension it by sliding the motor

away from the head. Tighten the 4 screws that hold the motor down.

3.

Install the limit switch brackets that hold the upper and lower quill limit switches in place. Manually move

the ballscrew up until you reach a hard stop. Now move the ballscrew down 1 turn of the ballscrew and set

the upper limit switch. The brackets are slotted to allow up and down adjustment. Move the ballscrew