Söllnerstr. 9 92637 Weiden

+49 (0)961 48 23 0 0

S7-USB user manual

15 / 85

2019/10/05 05:07

6.2 Programming software to use with direct

access

After you have adjusted and connected the PLC-VCOM or the programming adapter to the COM-port on

your computer, you will be able to connect with your programming software

to the PLC and work with it.

How you have to adjust your programming software is described in the following points:

6.2.1 PG2000 für S7 (V5.10)

1. Start the PG 2000 software by using the desktop link or by using the application entry in the start menu.

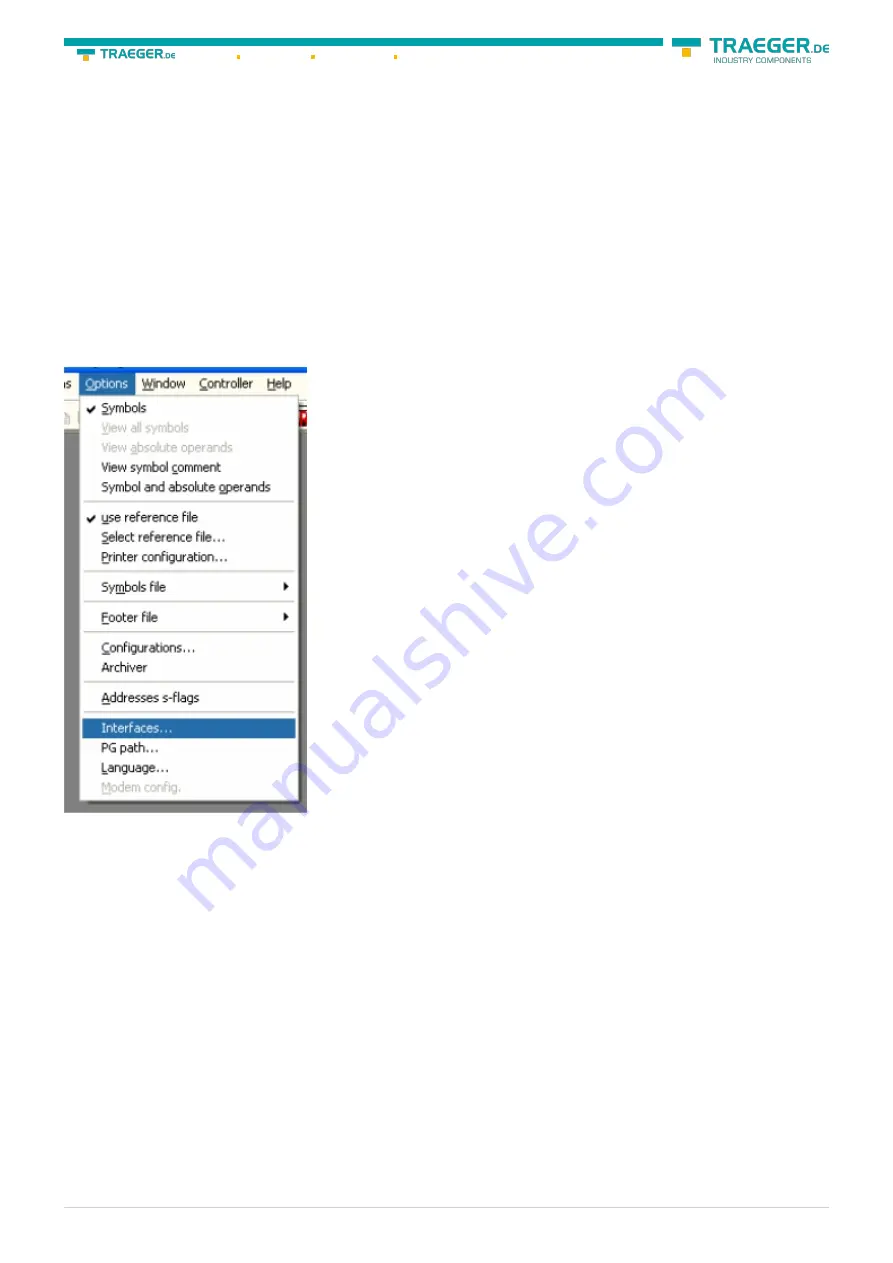

2. Choose from “View” ⇒ “S7-300/400” In the menu “Options“ click “Interfaces“..