Parameterization and configuration

Printed in the Federal Republic of Germany

©

TR-Electronic GmbH 1998, All Rights Reserved

03/09/2010

TR - ECE - BA - GB - 0014 - 03

Page 23 of 31

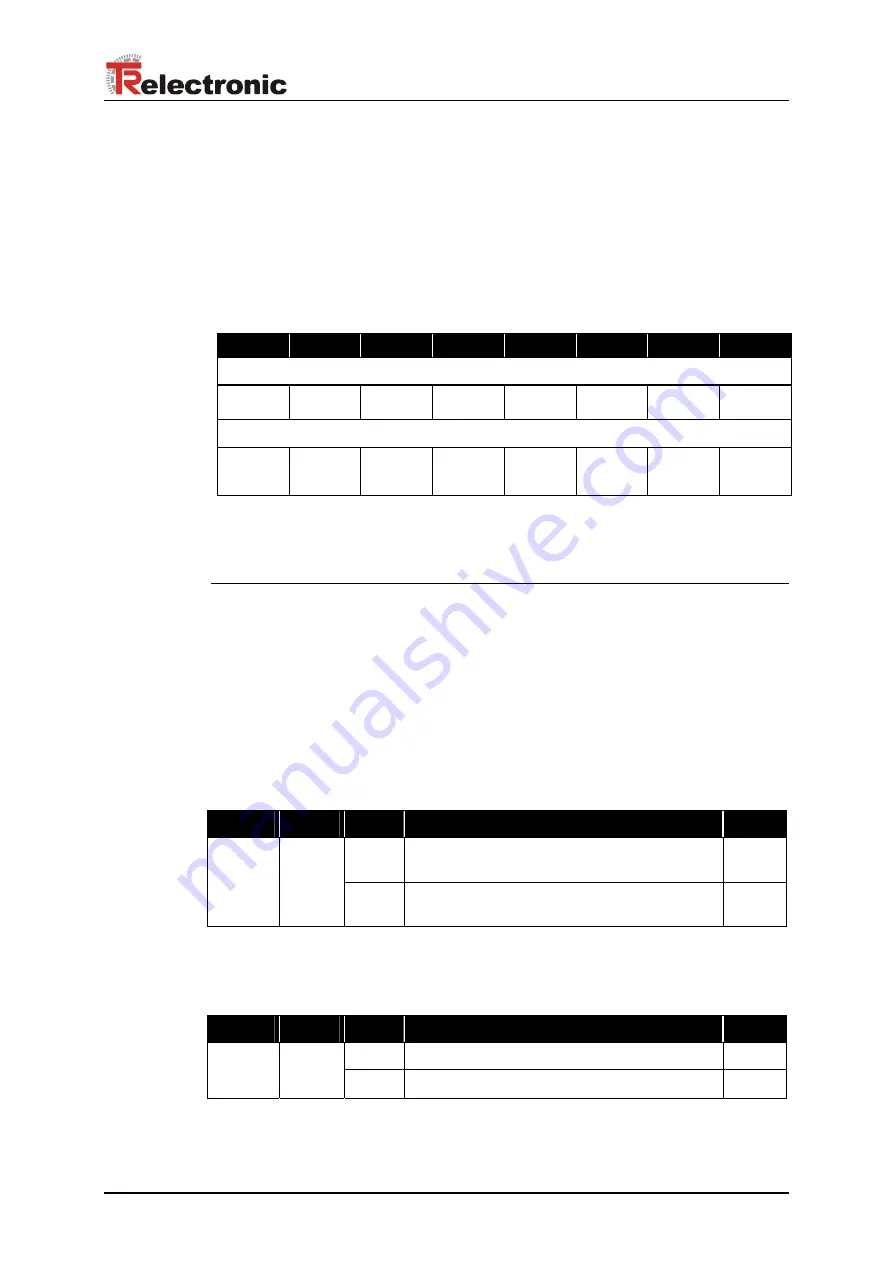

7.2.2 GET DATA CHECK - command

Instance 17, r/w

If the parameters are programmed via the "Parameter-Class", for taking over and test

the data, a Data-Check must be performed subsequently. The result (2 bytes) of the

SET DATA-CHECK can be read with GET DATA-CHECK. Are all bits of the returned

UINT value "0", no error is available. The possible errors are indicated in following

table:

GET DATA-CHECK:

Bit7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Low Byte Error Receive Buffer Master

0 0 0 0 0 0

Write-

error

Read-

error

High Byte Error Receive Buffer Master

0

Steps/Rev.

exceeded

3)

TNOS/Rev.

=0

upper

1)

SL

out of

range

upper

2)

OL

out of

range

lower

2)

OL

out of

range

lower

1)

SL

out of

range

0

An error bit can only then be reset when the data is corrected and a DATA-CHECK

command is executed.

1)

SL

= Safety Limit

2)

OL

= Operating Limit

3)

TNOS

= Total Number of Steps

7.3 Parameters / Range of values

7.3.1 Direction

Instance Service Value Description

Default

= 0

Position increasing clockwise

(view onto the shaft)

X

1 r/w

≠

0

Position decreasing clockwise

(view onto the shaft)

7.3.2 Output Code

Instance Service Value Description

Default

= 0

Binary code

X

2 r/w

≠

0

Gray code