0-7

SI UNITS

Meaning of SI

This manual uses SI units. SI represents the International System of Units, which was established to unify

the various systems of units used in the past for smoother international technical communication.

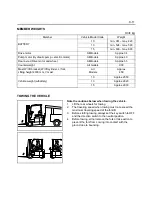

New Units Adopted in SI

<Reference>

* 1: X represents the value in SI units as converted from 1 [in conventional units], which can be

used as the rate for conversion between conventional and SI units.

* 2: In the past, kilogram [kg] representing mass was often used in place of weight kilogram [kgf],

which should be used as the unit of force.

Conversion between Conventional and SI Units

Equation for conversion

When converting, change the unit of the value in conventional or SI units to the one in the

conversion rate column in the table above before calculation. For example, when converting 100 W

to the value in conventional unit PS, first change it to 0.1 kW and divide by the conversion rate

0.735499.

Item

New unit

Conventional

unit

Conversion rate*

1

(1 [conventional unit] = X [SI

unit])

Force*

2

N (newton)

kgf

1 kgf = 9.80665 N

Torque

*2

(Moment)

N·m

kgf·cm

1 kgf·cm = 9.80665 N·m

Pressure*

2

Bar

kgf/cm

2

1 Bar = 1 kgf / cm

2

Pressure*

2

Pa (pascal)

kgf/cm

2

1 kgf/cm

2

= 98.0665 kPa = 0.0980665 MPa

↑

↑

mmHg

1 mmHg = 0.133322 kPa

Revolving speed

rpm

rpm

1 rpm = 1 r/min

Spring con-

N/mm

kgf/mm

1 kgf/mm = 9.80665 N/mm

Volume

l

cc

1 cc = 1 m

l

Power

W

PS system

1 PS = 0.735499 kW

Heat quantity

W·h

cal

1 kcal = 1.16279 W·h

Specific fuel

g/W·h

g/PS·h

1 g/PS·h = 1.3596 g/kW·h

Value in SI unit = Conversion rate

×

Value in conventional unit

Conversion rate: Figure corresponding

to X in the conversion rate column in

the table above

Value in conventional unit = Value in SI unit

÷

Conversion rate