P14785

P14787

P14790

Plastigage

Z11077

--

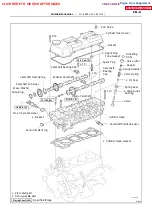

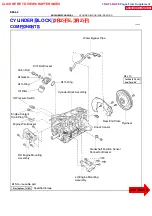

ENGINE MECHANICAL

CYLINDER BLOCK (2RZ--FE, 3RZ--F)

EM--67

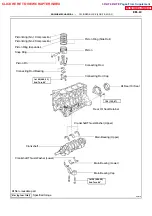

1 9 . CHE CK CRANKS HAFT T HRUS T CLE ARANCE

Using a dial indicator, measure the thrust clearance while prying

the crankshaft back and forth with a screwdriver.

Standard thrust clearance:

0.020 -- 0.220 mm (0.0008 -- 0.0087 in.)

Maximum thrust clearance:

0.30 mm (0.0118 in.)

If the thrust clearance is greater than maximum, replace the

thrust washers as a set.

Thrust washer thickness:

2.440 -- 2.490 mm (0.0961 -- 0.0980 in.)

20. RE MO V E MAI N BE ARI NG CAP S AND CHE CK O I L

CLE ARANCE

(a)

Uniformly loosen and remove the main bearing cap bolts,

in several passes, in the sequence shown.

(b)

Using the removed main bearing cap bolts, pry the main

bearing cap back and forth, and remove the main bearing

caps, lower bearings and (No.3 main bearing cap only)

lower thrust washers.

HINT:

S

Keep the lower bearing and main bearing cap to-

gether.

S

Arrange the main bearing caps and lower thrust

washers in correct order.

(c)

Lift out the crankshaft.

HINT:

Keep the upper bearings and upper thrust washers together

with the cylinder block.

(d)

Clean each main journal and bearing.

(e)

Check each main journal and bearing for pitting and

scratches.

If the journal or bearing is damaged, replace the bearings. If

necessary, grind or replace the crankshaft.

(f)

Place the crankshaft on the cylinder block.

(g)

Lay a strip of Plastigage across each journal.

(h)

Install the main bearing caps.

Torque:

1st 39 N

∙

m (400 kgf

∙

cm, 29 ft

∙

lbf)

2nd Turn 90

˚

NOTICE:

Do not turn the crankshaft.

(i)

Remove the main bearing caps.

(See procedure (a) and (b) above)

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE