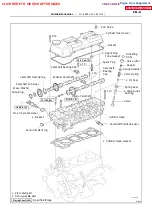

Z11379

45

˚

1.0 -- 1.4 mm

60

˚

P14703

EM0988

Deviation

EM0281

P14704

--

ENGINE MECHANICAL

CYLINDER HEAD (2RZ--FE)

EM--47

(2)

If the seating is too low on the valve face, use 60

˚

and 45

˚

cutters to correct the seat.

(e)

Hand--lap the valve and valve seat with an abrasive com-

pound.

(f)

After hand--lapping, clean the valve and valve seat.

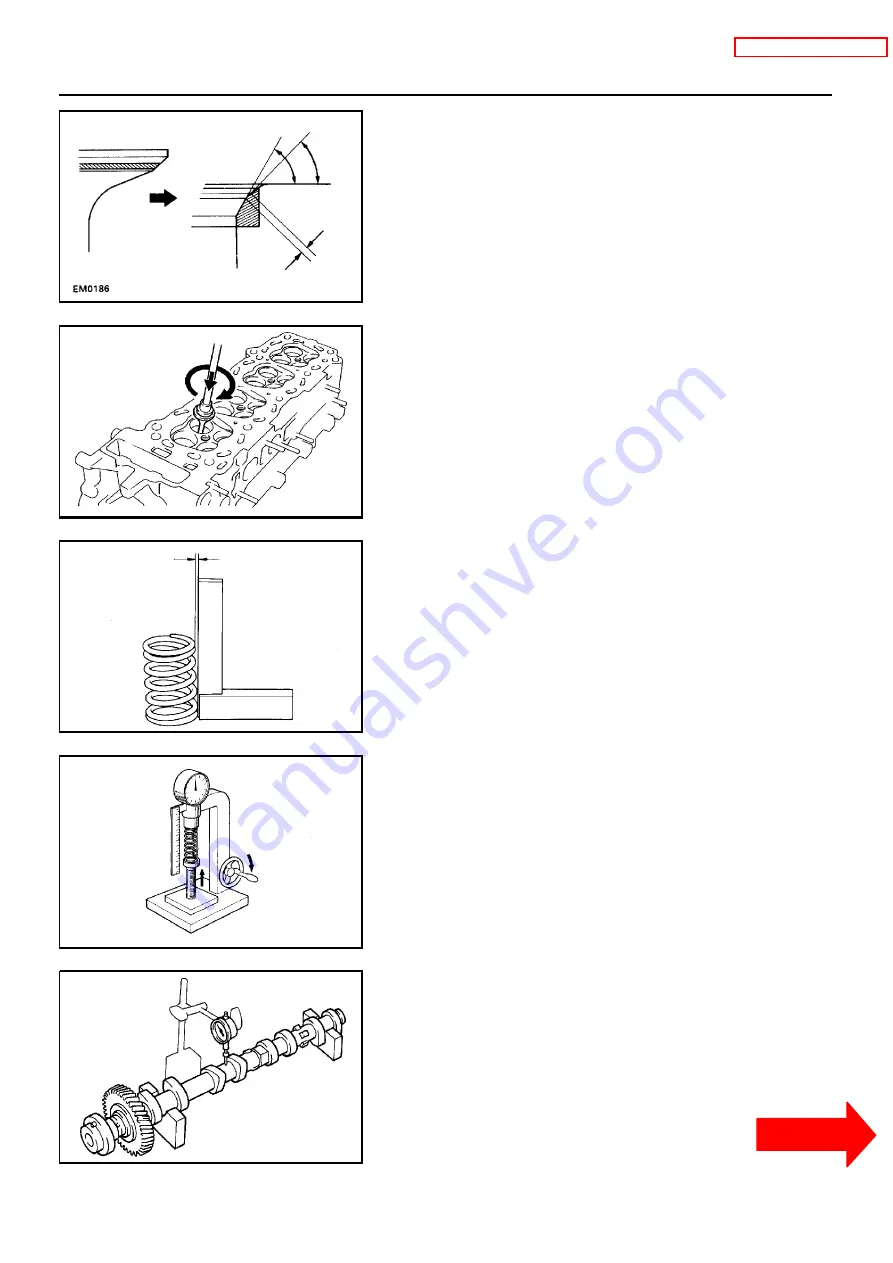

13. INSPECT VALVE SPRINGS

(a)

Using a steel square, measure the deviation of the valve

spring.

Maximum deviation:

2.0 mm (0.079 in.)

If the deviation is greater than maximum, replace the valve

spring.

(b)

Using a spring tester, measure the tension of the valve

spring at the specified installed length.

Installed tension:

162 -- 190 N (16.5 -- 19.4 kgf, 36.4 -- 42.8 lbf)

at 40.3 mm (1.580 in.)

If the installed tension is not as specified, replace the valve

spring.

14. INSPECT CAMSHAFT FOR RUNO UT

(a)

Place the camshaft on V--blocks.

(b)

Using a dial indicator, measure the circle runout at the

center journal.

Maximum circle runout:

0.06 mm (0.0024 in.)

If the circle runout is greater than maximum, replace the cam-

shaft.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE