No.

13

14

Item

HA control

Frequency fixed

operation (Test run)

Outline of specifications

1) This control is connected to telecontrol system or remote

start/stop I/F, etc, and start/stop are available by HA signal

input from the remote position.

2) This control outputs start/stop status to HA output terminal.

3) I/O specifications conform to JEMA regulations.

4) This control outputs [Operation OFF (STOP) signal] to HA

output terminal while self-cleaning operation. However selection

of [Operation ON (Operating) signal] is possible by changing

[0000 (At shipment)] of CODE No. (DN) [CC] to [0001]. In this

case, if HA is input during self-clean operation during operation

of the air conditioner, the self-clean operation is not performed.

(Unit stops.)

<In case of wired remote controller>

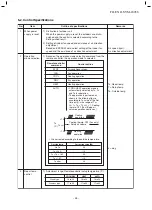

1) When pushing [TEST] button for 4 seconds or more, [TEST]

is displayed on the display screen and the mode enters in

Test run mode.

2) Push [ON/OFF] button.

3) Using [MODE] button, set the mode to [COOL] or [HEAT].

• Do not use other mode than [COOL]/[HEAT] mode.

• During test run operation, the temperature cannot be

adjusted.

• An error is detected as usual.

• A frequency fixed operation is performed.

4) After the test run, push [ON/OFF] button to stop the operation.

(Display in the display part is same as the procedure in Item 1.)

5) Push [TEST] button to clear the test run mode.

([TEST] display in the display part disappears and the

status returns to the normal stop status.)

Remarks

In the group opera-

tion, use this control

by connecting to

either header or

follower indoor unit.

Command frequency

is approximately [S7]

15

Filter sign display

(Except wireless

type)

[FILTER

] goes on.

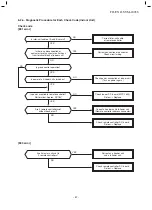

1) The operation time of the indoor fan is calculated, the filter reset

signal is sent to the remote controller when the specified time

(2500H) has passed, and it is displayed on LCD.

2) When the filter reset signal has been received from the

remote controller, time of the calculation timer is cleared.

In this case, the measurement time is reset if the specified

time has passed, and display on LCD disappears.

<In case of wireless remote controller>

1) When TEMPORARY button is pushed for 10 seconds or

more, “Pi!” sound is heard and the operation changes to test

run. After approx. 3 minutes, a cooling operation starts

forcedly.

Check cool air starts blowing. If the operation does not start,

check wiring again.

2) To stop a test operation, push TEMPORARY button once

again (Approx. 1 second).

Check wiring / piping of the indoor and outdoor units in test

run.

TEMPORARY button

FILE NO. SVM-18038

- 33 -