– 81 –

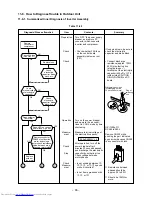

(5) Troubleshooting for remote controller

<Primary check>

Check that A or B selected on the main unit is matched with A or B selected on the remote controller.

NO

YES

Push the START/STOP button.

Is transmission

mark indicated?

The unit does not beep at all.

Operation lamp on indoor

unit is not indicated.

NOTE : After replacing batteries,

push the RESET button

with a tip of a pencil.

Is receiver

on indoor unit

exposed to

direct sunlight?

Avoid direct

sunlight.

Is there any

thyristor

fluorescent light

nearby?

Keep indoor unit

away from thyristor

fluorescent light.

Does indoor unit

operate when moving

remote controller

near receiver or

indoor unit?

Batteries are

exhausted.

Does radio sound

is affected by remote

controller when a signal is

transmitted at distance of

5 cm from radio?

Is transmission

mark indicated?

P.C. board

is defective.

Replace

P.C. board.

Replace

batteries.

Replace

remote controller.

Normal

operation

Remote controller

is defective.

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

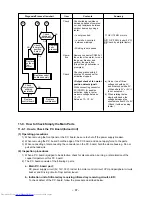

Does indoor unit

start to operate by

automatic restart

function?

Push the START/

STOP button

Does indoor unit

beep and operate?

Push RESET button

on remote controller

with tip of pencil.

Summary of Contents for RAS-3M18SACV-E

Page 21: ... 21 4 2 Outdoor Unit RAS 3M18SAV E RAS 3M18SACV E ...

Page 110: ... 110 MCC 1438 ...

Page 111: ... 111 MCC 818 ...