FILE NO. SVM-12056

A

Die

Pipe

Fig. 10-4-4

CAUTION

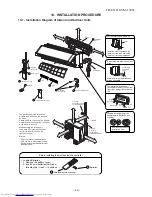

<Tightening connection>

Align the centers of the connecting pipes and tighten

the flare nut as far as possible with your fingers. Then

tighten the nut with a spanner and torque wrench as

shown in the figure.

Half union

Flare nut

Externally

threaded side

Internally

threaded side

Use a wrench

to secure.

Use a torque wrench

to secure.

CAUTION

Outer dia. of copper pipe

R410A

∅

6.35

1.5 to 2.0

∅

12.70

2.0 to 2.5

Imperial (wing nut type)

Fig. 10-4-5

(Unit : N·m)

Outer dia.

Tightening torque

of copper pipe

∅

6.35 14 to 18 (1.4 to 1.8 kgf·m)

∅

12.70 50 to 62 (5.0 to 6.2 kgf·m)

.

CAUTION

•

Do not apply excess torque.

•

Otherwise, the nut may crack depending on the

conditions.

<Tightening orque of flare pipe connections>

The operating oressure of R410A is higher than that

of R22 (approx. 1.6 times). It is therefore necessary

to firmly tighten the flare pipe connecting sections

(which connect the indoor and outdoor units) up to the

specified tightening torque. Incorrect connections may

cause not only a gas leakage, but also damage to the

refrigeration cycle.

10-4-

4

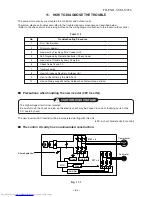

. Evacuating

After the piping has been connected to the indoor unit,

you can perform the air purge together at once.

AIR PURGE

Evacuate the air in the connecting pipes and in the

indoor unit using a vacuum pump. Do not use the

refrigerant in the outdoor unit.

For details, see the manual of the vacuum pump.

Fig. 10-4-6

Flare at indoor unit side

Flare at outdoor unit side

<Using a vacuum pump>

Be sure to use a vacuum pump with counter-flow

prevention function so that inside oil of the pump does

not flow backward into pipes of the air conditioner

when the pump stops.

1. Connect the charge hose from the manifold valve to

the service port of the packed valve at gas side.

2. Connect the charge hose to the port of the vacuum

pump.

3. Open fully the low pressure side handle of the

gauge manifold valve.

4. Operate the vacuum pump to start evacuating.

Perform evacuating for about 15 minutes if the piping

length is 20 meters. (15 minutes for 20 meters)

(assuming a pump capacity of 27 liters per minute.)

Then confirm that the compound pressure gauge

reading is

−

101 kPa (

−

76 cmHg).

5. Close the low pressure side valve handle of the

gauge manifold valve.

6. Open fully the valve stem of the packed valves

(both gas and liquid sides).

7. Remove the charging hose from the service port.

8. Securely tighten the caps on the packed valves.

(If oil inside of the vacuum pump enters the air conditioner,

which use R410A, refrigeration cycle trouble may happen.)

–

60

–

Summary of Contents for RAS-18N3AV2-E

Page 108: ...TOSHIBA CARRIER THAILAND CO LTD ...