Checking the Spark Plug

1. Look at the center of the spark plug(s)

(Figure 31). If you see light brown or gray on

the insulator, the engine is operating properly.

A black coating on the insulator usually means

the air cleaner is dirty.

Important:

Never clean the spark

plug(s). Always replace the spark plug(s)

when it has a black coating, worn

electrodes, an oily film, or cracks.

2. Check the gap between the center and side

electrodes (Figure 31). Bend the side electrode

(Figure 31) if the gap is not correct.

Figure 31

1. Center electrode insulator

3. Air gap (not to scale)

2. Side electrode

Installing the Spark Plug(s)

1. Install the spark plug(s). Make sure that the

air gap is set correctly.

2. Tighten the spark plug(s) to 11 ft.-lb. (15 N·m).

3. Push the wire(s) onto the spark plug(s)

Servicing the Battery

Check the electrolyte level in the battery every

25 hours. Always keep the battery clean and fully

charged. Use a paper towel to clean the battery

case. If the battery terminals are corroded, clean

them with a solution of four parts water and one

part baking soda. Apply a light coating of grease

to the battery terminals to prevent corrosion.

Voltage: 12 v

Removing the Battery

Battery terminals or metal tools could short

against metal tractor components causing

sparks. Sparks can cause the battery gasses

to explode, resulting in personal injury.

•

When removing or installing the battery,

do not allow the battery terminals to

touch any metal parts of the tractor.

•

Do not allow metal tools to short between

the battery terminals and metal parts of

the tractor.

1. Disengage the PTO and move the control

levers to the neutral locked position and apply

the parking brake.

2. Stop the engine, remove the key, and wait for

all moving parts to stop before leaving the

operating position.

3. Tip the seat forward to see the battery.

4. Disconnect the negative (black) ground cable

from the battery post (Figure 32).

Incorrect battery cable routing could

damage the tractor and cables causing

sparks. Sparks can cause the battery

gasses to explode, resulting in personal

injury.

•

Always disconnect the negative

(black) battery cable before

disconnecting the positive (red)

cable.

•

Always connect the positive (red)

battery cable before connecting the

negative (black) cable.

5. Slide the rubber cover up the positive (red)

cable. Disconnect the positive (red) cable from

the battery post (Figure 32).

6. Remove the battery hold-down (Figure 32) and

lift the battery from the battery tray.

27

Summary of Contents for TimeCutter ZX440

Page 7: ...Slope Chart 7 ...

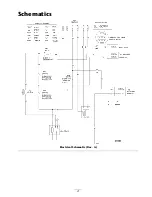

Page 41: ...Schematics Electrical Schematic Rev A 41 ...

Page 42: ...Notes ...

Page 43: ...Notes ...

Page 44: ......