Maintenance

Note:

Determine the left and right sides of the machine from the normal operating position.

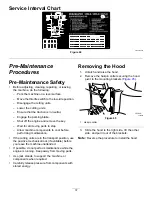

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the first hour

• Torque the wheel nuts.

After the first 10 hours

• Torque the wheel nuts.

• Check the condition and tension of all belts.

• Change the hydraulic filter.

After the first 50 hours

• Change the oil and oil filter.

Before each use or daily

• Inspect the seat belt(s) for wear, cuts, and other damage. Replace the seat belt(s) if

any component does not operate properly.

• Check the level of the engine oil.

• Check the coolant level of the engine.

• Check the level of the hydraulic fluid.

• Check the tire pressure.

• Check the interlock system.

• Drain the water separator.

• Clean debris off of the radiator.

• Check the hydraulic lines and hoses.

Every 25 hours

• Check the electrolyte level (if machine is in storage, check every 30 days).

Every 50 hours

• Lubricate all bearings and bushings (daily when conditions are dusty and dirty).

Every 100 hours

• Check the condition and tension of all belts.

Every 150 hours

• Change the oil and oil filter.

Every 200 hours

• Torque the wheel nuts.

• Service the air cleaner (more frequently in extremely dusty or dirty conditions).

• Check the adjustment of the parking brake.

• Change the hydraulic filter.

Every 400 hours

• Check the fuel lines and connections.

• Replace the fuel filter canister.

• Change the hydraulic fluid.

Every 2 years

• Drain and clean the fuel tank.

CAUTION

If you leave the key in the ignition switch, someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition before you do any maintenance.

35

Summary of Contents for 03820

Page 53: ...Notes ...

Page 54: ...Notes ...