泰智科技

Shenzhen Topwisdom Technology Co., Ltd

60

4.4.2 Carving Gradient Sketch Map

Fig. 4-27

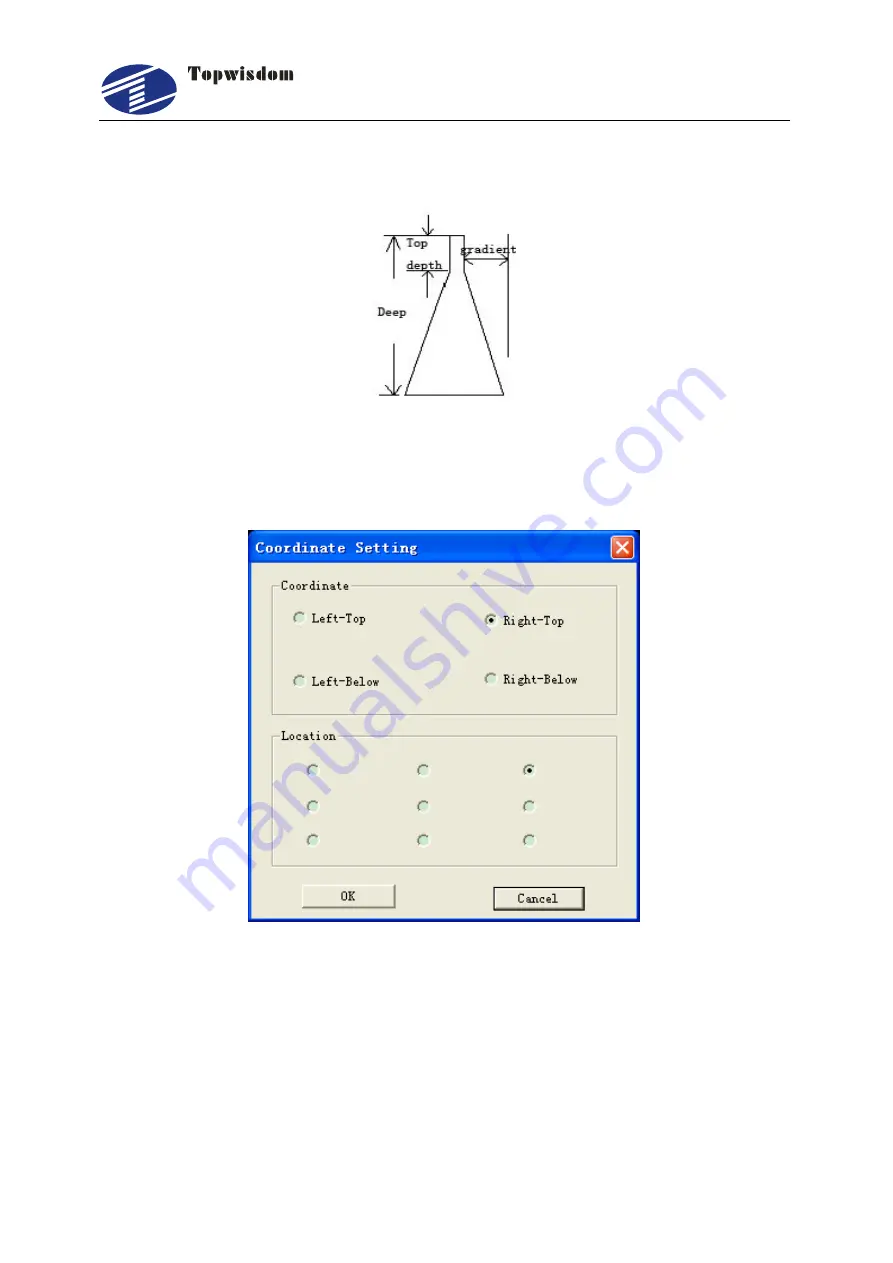

4.4.3 Coordinate System

Fig. 4-28

Coordinate: Coordinate must match original position of the machine. On the same

machine can't literally change the coordinate system

Location: The position of laser head is the start position before cutting. As shown in

figure below, there are 9 locations of laser head relative to the position of graphic. The

red cross is the position of laser head.