7

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1. Before installation, be sure to remove all protective seals.

2. Before installing the product, blow out the inlet piping to remove any piping scraps,

dirt and oil. Close the inlet valve after blowdown.

3. Install the product so that the arrow on the body is pointing in the direction of flow.

4. The trap should be inclined no more than 5° in any plane.

5. Install a condensate outlet valve and outlet piping.

6. Open the inlet and outlet valves and check to make sure that the product functions

properly.

If there is a problem, determine the cause using the “Troubleshooting” section in this manual.

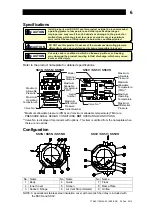

Tolerance Angle for Installation - 5°

(SS3N / SS5N / SS5NH)

Tolerance Angle for Installation - 5°

(SS3V / SS5V / SS5VH)

Install on a horizontal pipe with the nameplate

facing upwards and the arrow pointing in the

direction of flow

Install on a verticle pipe with the inlet on top,

the outlet on the bottom and the arrow

pointing in the direction of flow

NOTE: For products with socket weld connections the insulation cover shipped with the

product should be attached after the products is welded onto the pipe and after its

surface has cooled to room temperature.

For attaching the insulation cover, see the instruction below.

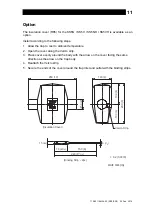

<How to attach the insulation cover>

Short tape

Long tape

Step 1. Wrap the included sealing tape around the inlet and outlet

connection at each end of the trap (3 turns for each).

Step 2. Fit the two halfshells of the insulation cover around the trap

until the 5 tabs and 5 holes are perfectly aligned.

A nameplate is affixed to the insulation cover. Make sure

that direction of the arrow on the nameplate matches the

direction of condensate flow.

Step 3. Using the included aluminum tape, seal the area where the

halfshells meet. Then wrap 3 more turns of sealing tape over

the top of the sealing tape applied in step 1.

172-65119MAJ-03 (SS3/SS5) 25 Feb 2014